In a previous post, we have already written about the mechanical stability of cellular glass. We even have discussed the static fatigue limit of glass and so cellular glass. These posts, based on acoustic emission experiments and self organized criticality (1988) take into account the interaction between the different cells. In case a cell breaks, the load is redistributed over the neighbor cells.

In a previous post, we have already written about the mechanical stability of cellular glass. We even have discussed the static fatigue limit of glass and so cellular glass. These posts, based on acoustic emission experiments and self organized criticality (1988) take into account the interaction between the different cells. In case a cell breaks, the load is redistributed over the neighbor cells.

In a 1981 paper of the NASA, the mechanical stability of cellular glass is experimentally and theoretically studied. I give the abstract in the following:

Cellular glasses are prime candidate materials for the structural substrate of mirrored glass for solar concentrator reflecting panels. These materials possess properties desirable for this application such as high stiffness to weight ratio, dimensional stability, projected low cost in mass production and, importantly, a close match in thermal expansion coefficient with that of the mirror glass. These materials are brittle, however, and susceptible to mechanical failure from slow crack growth caused by a stress corrosion mechanism.

Cellular glasses are prime candidate materials for the structural substrate of mirrored glass for solar concentrator reflecting panels. These materials possess properties desirable for this application such as high stiffness to weight ratio, dimensional stability, projected low cost in mass production and, importantly, a close match in thermal expansion coefficient with that of the mirror glass. These materials are brittle, however, and susceptible to mechanical failure from slow crack growth caused by a stress corrosion mechanism.

This report details the results of one part of a program established to develop improved cellular glasses and to characterize the behavior of these and commercially available materials. Commercial and developmental cellular glasses were tested and analyzed using standard testing techniques and models developed from linear fracture mechanics. Two models describing the fracture behavior of these materials are developed. Slow crack growth behavior in cellular glass was found to be more complex than that encountered in dense glasses or ceramics. The crack velocity was found to be strongly dependent upon water vapor transport to the tin of the moving crack. The existence of a

static fatigue limit was not conclusively established, however, it is speculated that slow crack growth behavior in Region I may be slower, by orders of magnitude, than that found in dense glasses.

The motivation of NASA was already described in a previous post and it even already applied to replace concrete. On top of that, cellular glass and glass have the same thermal expansion coefficient if the foam is made from the same glass. This makes cellular glass as the preferred support for mirrors.

The mechanical stability was measured by measuring the velocity of a single crack under a load. In a previous post, we described how the acoustic emisson detects the interaction of many micro cracks. In fact, these microcracks are a complex system inducing small and large events. We prefer this method and not the study of a single macroscopic crack. The acoustic emission technique allows to measure the static fatigue limit of cellular glass.

Foam glass gravel is a highly stable and versatile product that has been successfully used in building and infrastructure construction in Europe for over twenty-five years. Our mission is to bring this product to the construction industry in North America.

Foam glass gravel is a highly stable and versatile product that has been successfully used in building and infrastructure construction in Europe for over twenty-five years. Our mission is to bring this product to the construction industry in North America.

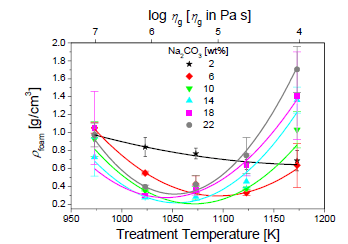

Foaming is commonly achieved by adding metal oxides or metal carbonates (foaming agents) to glass powder. At elevated temperature, the glass melt becomes viscous and the foaming agents decompose or react to form gas, resulting in foamy glass melt. Subsequent cooling to room temperature, lead to solid foam glass. Metal carbonates decompose due to surface reaction. Based on Na2CO3, we show the reaction is fast and the glass transition is changed considerably. We propose the reaction rate is dependent on contact area between glass melt and Na2CO3, melt viscosity and Na+ diffusion.

Foaming is commonly achieved by adding metal oxides or metal carbonates (foaming agents) to glass powder. At elevated temperature, the glass melt becomes viscous and the foaming agents decompose or react to form gas, resulting in foamy glass melt. Subsequent cooling to room temperature, lead to solid foam glass. Metal carbonates decompose due to surface reaction. Based on Na2CO3, we show the reaction is fast and the glass transition is changed considerably. We propose the reaction rate is dependent on contact area between glass melt and Na2CO3, melt viscosity and Na+ diffusion.  A method is developed for optimising process parameters. Characteristic temperatures are derived from a deformation curve and the deformation rate curve. Maximum expansion rate was linked to closed porosity. Using this knowledge the method is applied to literature data to analyse for optimal conditions. The resulting conditions were in agreement with industrial conditions. Since no foam glass properties are necessary to measure, the method allows fast investigation of process parameters.

A method is developed for optimising process parameters. Characteristic temperatures are derived from a deformation curve and the deformation rate curve. Maximum expansion rate was linked to closed porosity. Using this knowledge the method is applied to literature data to analyse for optimal conditions. The resulting conditions were in agreement with industrial conditions. Since no foam glass properties are necessary to measure, the method allows fast investigation of process parameters.  The melt viscosity is an important parameter for foam growth. We compared bubble- and crystal free melt viscosity with foam density and show in order to minimise the foam density, the heat-treatment should be performed in the viscosity regime of 103.7-106 Pa s.

The melt viscosity is an important parameter for foam growth. We compared bubble- and crystal free melt viscosity with foam density and show in order to minimise the foam density, the heat-treatment should be performed in the viscosity regime of 103.7-106 Pa s.  dependent on porosity or foam density. Foam glasses made from CRT panel glass and different foaming agents confirm this trend at high porosity level (85-97%). The experimental data suggests the solid conductivity is dependent on the foaming agent applied.

dependent on porosity or foam density. Foam glasses made from CRT panel glass and different foaming agents confirm this trend at high porosity level (85-97%). The experimental data suggests the solid conductivity is dependent on the foaming agent applied.

In 1991, he became a professor at the

In 1991, he became a professor at the  Since 1994, he has been a professor at the

Since 1994, he has been a professor at the  I got a

I got a  On the other hand, the gas – pycnometer is a nice and simple instrument to measure the volume of the closed cells. If this volume is in line with the geometric volume, we know that the cells are closed and that the mu-value will be above 40000. Because this method takes a few minutes, it is the ultimate instrument for QC in factories where open (acoustic ) and closed cell material (thermal insulation) is produced.

On the other hand, the gas – pycnometer is a nice and simple instrument to measure the volume of the closed cells. If this volume is in line with the geometric volume, we know that the cells are closed and that the mu-value will be above 40000. Because this method takes a few minutes, it is the ultimate instrument for QC in factories where open (acoustic ) and closed cell material (thermal insulation) is produced.

One function of CRT glass is to absorb the X-ray radiation, generated by the high velocity electrons bombarding the front panel with phosphor. For this important function, PbO and BaO are introduced in the glass. PbO is introducing a brown color into the screen after long use. For that reason, the PbO is replaced by SrO in the front panel of the color television CRT. This and more is well explained in the following

One function of CRT glass is to absorb the X-ray radiation, generated by the high velocity electrons bombarding the front panel with phosphor. For this important function, PbO and BaO are introduced in the glass. PbO is introducing a brown color into the screen after long use. For that reason, the PbO is replaced by SrO in the front panel of the color television CRT. This and more is well explained in the following  Another

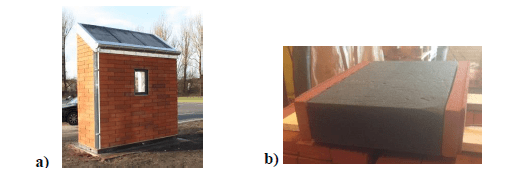

Another  Das Ziel des Projektes liegt in der Entwicklung eines nachhaltigen, brandfesten und tragfähigen vakuum-isolierten Bauelementes (VIP), mit erheblich verbesserten Eigenschaften im Vergleich zum Stand der Technik. Dazu sollen die derzeitig für den Stützkern verwendeten Werkstoffe durch Schaumglasstrukturen substituiert werden.

Das Ziel des Projektes liegt in der Entwicklung eines nachhaltigen, brandfesten und tragfähigen vakuum-isolierten Bauelementes (VIP), mit erheblich verbesserten Eigenschaften im Vergleich zum Stand der Technik. Dazu sollen die derzeitig für den Stützkern verwendeten Werkstoffe durch Schaumglasstrukturen substituiert werden. Also in this case, it is mentioned to develop a recipe for open cell cellular glass, which will be evacuated later on. The evacuation has to be done to a very low pressure because the mean free path of the gas molecules must be larger than the cell size. A very nice introduction to vacuum technology, written by

Also in this case, it is mentioned to develop a recipe for open cell cellular glass, which will be evacuated later on. The evacuation has to be done to a very low pressure because the mean free path of the gas molecules must be larger than the cell size. A very nice introduction to vacuum technology, written by  Breathing walls are requested due to the “

Breathing walls are requested due to the “ The passive housing system is the well known. Air tight walls with a very large thermal resistance (U=0.1 W/m2K) where all the fresh air comes from forced ventilation. The intake air is heated by the air leaving the building with a heat exchanger between both flows. Due to the low heat flow, the wall may be a source of interstitial condensation, generating mold while also the heat exchanger needs regular cleaning to avoid mold. On top of that, the limited diameter of the ventilation channels is the reason of high air speed regions in the house, which is not comfortable. It is clear that passive housing is not the favorite for people suffering from the sick building syndrome.

The passive housing system is the well known. Air tight walls with a very large thermal resistance (U=0.1 W/m2K) where all the fresh air comes from forced ventilation. The intake air is heated by the air leaving the building with a heat exchanger between both flows. Due to the low heat flow, the wall may be a source of interstitial condensation, generating mold while also the heat exchanger needs regular cleaning to avoid mold. On top of that, the limited diameter of the ventilation channels is the reason of high air speed regions in the house, which is not comfortable. It is clear that passive housing is not the favorite for people suffering from the sick building syndrome. On the other hand, the breathing wall system is solving all the above problems. In a

On the other hand, the breathing wall system is solving all the above problems. In a  It is clear that open cell cellular glass can play a role in this dynamic insulation but I do not believe in breathing (dynamic insulation) walls due to wind problems. However, a breathing ceiling would be a nice application. Fresh air is pumped through a ceiling, constructed with open cell cellular glass, generating a ventilation over a large surface with extremely low air velocity. Besides ventilation, the open cell cellular glass serves also as acoustic absorber. I can imagine that this a perfect system for a student restaurant at the university. Ventilation and acoustic absorption, besides food are there the main issues.

It is clear that open cell cellular glass can play a role in this dynamic insulation but I do not believe in breathing (dynamic insulation) walls due to wind problems. However, a breathing ceiling would be a nice application. Fresh air is pumped through a ceiling, constructed with open cell cellular glass, generating a ventilation over a large surface with extremely low air velocity. Besides ventilation, the open cell cellular glass serves also as acoustic absorber. I can imagine that this a perfect system for a student restaurant at the university. Ventilation and acoustic absorption, besides food are there the main issues.