Radon is a natural radioactive gas that causes cancer when it is present in the lungs. In regions with a lot of Uranium and Thorium in the soil, this Radon gas is present in higher concentrations. When accumulated in a building, a real health problem is present being the second cause of lung cancer. The situation in Europe is shown in the following picture. Everything more tha yellow deserves measures against radiation.

Radon is a natural radioactive gas that causes cancer when it is present in the lungs. In regions with a lot of Uranium and Thorium in the soil, this Radon gas is present in higher concentrations. When accumulated in a building, a real health problem is present being the second cause of lung cancer. The situation in Europe is shown in the following picture. Everything more tha yellow deserves measures against radiation.

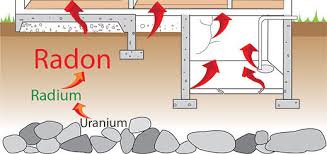

The American government educates its citizen how to build houses to avoid Radon accumulation like shown in this leaflet. The standard method is to use a ventilated space under the floor.

The American government educates its citizen how to build houses to avoid Radon accumulation like shown in this leaflet. The standard method is to use a ventilated space under the floor.

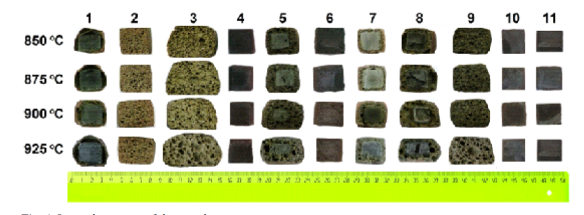

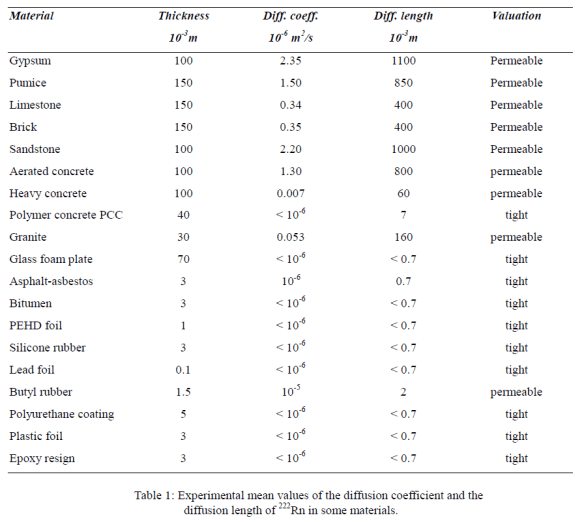

The need of this ventilated space is clear if cellular glass is not taken into account. A German paper of Keller shows how Radon diffuison is measured in building materials and gives a tabel (see hereunder) with the diffusion length for Radon. This is the length Radon diffuses before it decays with harmfull radiation. A Radon barrier should have a thickness three times this diffusion length to withstand 95% of the Radon.

It is clear that a concrete beam of 200mm thickness is on the limit and that for polymer materials the joints are uppermost important. Indeed, not using a ventilated space under these systems is a risk.

But like already mentionned in a previous post, cellular glass boards are a perfect light barrier against radon. A compact layer of cellular glass boards in bitumen is a perfect screen (100 mm cellular glass is 100 times the diffusion limit of Radon) serving also as thermal insulation and avoiding expensive radon ventilation systems. The bitumen joints are the only risk but using large GLAPOR cellular glass boards 280 x 120 cm reduces this risk for radon leaks with a factor 12 compared with 59.9 x 44.9 cm boards.

But like already mentionned in a previous post, cellular glass boards are a perfect light barrier against radon. A compact layer of cellular glass boards in bitumen is a perfect screen (100 mm cellular glass is 100 times the diffusion limit of Radon) serving also as thermal insulation and avoiding expensive radon ventilation systems. The bitumen joints are the only risk but using large GLAPOR cellular glass boards 280 x 120 cm reduces this risk for radon leaks with a factor 12 compared with 59.9 x 44.9 cm boards.

On top of that, if for passive housing these GLAPOR boards are installed on a thick layer of (implicit ventilated) GLAPOR cellular glass gravel with the RDS system, even the presence of negligible concentrations of Radon in the house is eliminated and a passive housing standard thermal insulation is installed under the floor at a very good price.