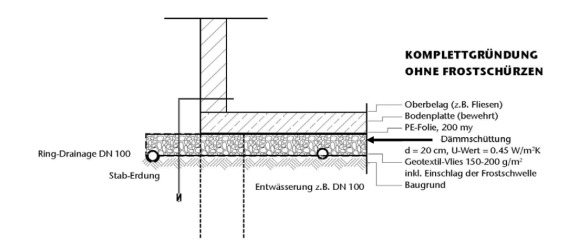

Fraunhofer Institute for Building Physics investigated in real life the use of foamed glass gravel as a basement wall thermal insulation and under the concrete slab of a building. More details can be found in this nice foamed glass gravel document.

Fraunhofer Institute for Building Physics investigated in real life the use of foamed glass gravel as a basement wall thermal insulation and under the concrete slab of a building. More details can be found in this nice foamed glass gravel document.

The summary of the results is published in English, German and French. They conclude that the design value for the thermal resistance is not reached for the basement wall insulation, which is a less popular application. On the other hand, the design values are exceeded for the floor insulation system, where foamed glass gravel is used under the concrete slab.

In the report, the authors also explain that the calculated and measured values only match when air movement and latent heat is included in the calculation. Air movement is equivalent with convection (free or forced). Latent heat means that the evaporation of the humidity extracts heat from the gravel, which creates an extra heat loss.

Indeed, the convection spreadsheet allows to find out that indeed free convection is present in the gravel besides the basement wall. With an intrinsic permeability of 1e-7 m² for gravel, a 2.2m thick layer of gravel and 0.1 W/mK thermal conductivity, it is clear that the free convection in winter (10°C temperature gradient) has the same magnitude as the assumed thermal conductivity.

On the other hand, the law of Darcy shows that with the same permeability and a pressure drop of 10Pa over the house, important forced convection is present in the gravel under the concrete slab. This forced convection induces an important heat loss during winter.

On the other hand, the law of Darcy shows that with the same permeability and a pressure drop of 10Pa over the house, important forced convection is present in the gravel under the concrete slab. This forced convection induces an important heat loss during winter.

However, the RDS concept of GLAPOR, where cellular glass boards enclose the gravel and so avoid water ingress and forced convection, eliminates this problem. As a consequence, this RDS-system allows to exceed largely the design value for gravel thermal insulations under the concrete slab.

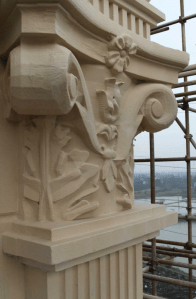

Standard gravel system with possible water ingress and forced convection due to wind

GLAPOR RDS-system where the gravel is protected from water ingress and forced convection due to wind.

Forced and free convection in permeable thermal insulation can be very important and is most of the time neglected. But in this case, GLAPOR improved the situation proactive. The evaporation of humidity in insulation or the heat pipe effect will be discussed in a following blog.

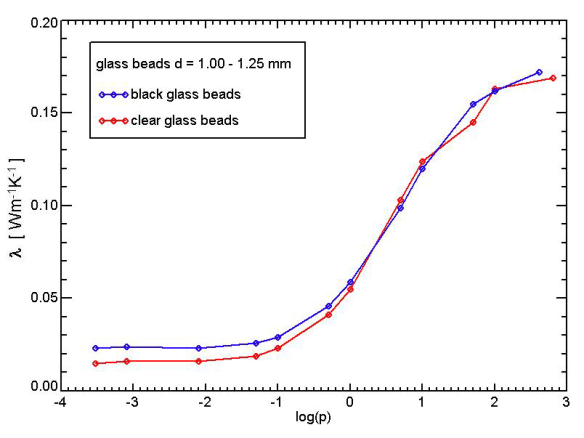

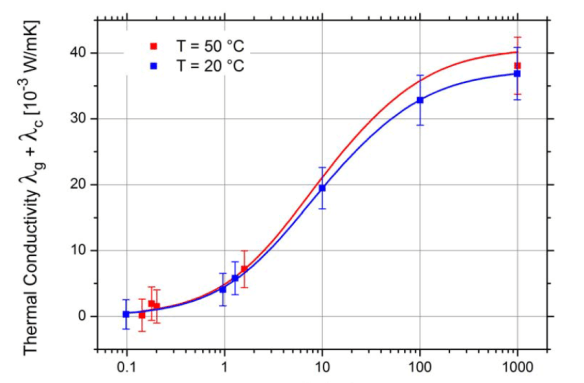

We also measured the thermal conductivity with the hot wire method and found 0.052 W/mK at 20°C with this two-dimensional method. It is claimed that this cellular glass is foamed with technical carbon. Therefore, we did a comparative test with Pinosklo and

We also measured the thermal conductivity with the hot wire method and found 0.052 W/mK at 20°C with this two-dimensional method. It is claimed that this cellular glass is foamed with technical carbon. Therefore, we did a comparative test with Pinosklo and