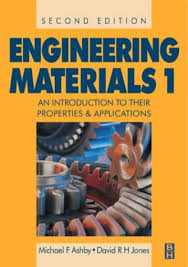

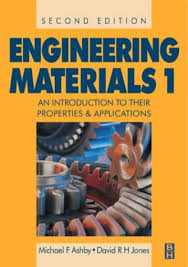

Michael F. Ashby is a Cambridge University professor about new (and old) materials. By accident, I found his textbook about engineering materials Vol. 1 on research gate.

Michael F. Ashby is a Cambridge University professor about new (and old) materials. By accident, I found his textbook about engineering materials Vol. 1 on research gate.

The textbook describes the important physical properties and physcis behind these properties. But also the availability and price are given some attention.

The book is of course illustrated with case studies. Hereunder we cite the case study about the support of a large telescope mirror.

The book is of course illustrated with case studies. Hereunder we cite the case study about the support of a large telescope mirror.

Introduction

The worlds largest single-mirror reflecting-telescope is sited on Mount Semivodrike,

near Zelenchukskaya in the Caucasus Mountains. The mirror is 6m (236 inches) in

diameter, but it has never worked very well. The largest satisfactory single-mirror

reflector is that at Mount Palomar in California; it is 5.08 m (200 inches) in diameter. To

be sufficiently rigid, the mirror (which is made of glass) is about 1 m thick and weighs

70 tonnes.*

The cost of a 5m telescope is, like the telescope itself, astronomical – about UKE120 m or US$180 m. This cost varies roughly with the square of the weight of the mirror so it rises very steeply as the diameter of the mirror increases. The mirror itself accounts for about 5% of the total cost of the telescope. The rest goes on the mechanism which holds, positions and moves the mirror as it tracks across the sky

The cost of a 5m telescope is, like the telescope itself, astronomical – about UKE120 m or US$180 m. This cost varies roughly with the square of the weight of the mirror so it rises very steeply as the diameter of the mirror increases. The mirror itself accounts for about 5% of the total cost of the telescope. The rest goes on the mechanism which holds, positions and moves the mirror as it tracks across the sky

(Fig. 7.1). This must be so stiff that it can position the mirror relative to the collecting system with a precision about equal to that of the wavelength of light. At first sight, if you double the mass M of the mirror, you need only double the sections of the

structure which holds it in order to keep the stresses (and hence the strains and deflections) the same, but this is incorrect because the heavier structure deflects under its own weight. In practice, you have to add more section to allow for this so

that the volume (and thus the cost) of the structure goes as M2. The main obstacle

to building such large telescopes is the cost. Before the turn of the century, mirrors were made of speculum metal, a copper-tin alloy (the Earl of Rosse (1800-18671, who lived in Ireland, used one to discover spiral galaxies) but they never got bigger than 1 m because of the weight. Since then, mirrors have been made of glass, silvered on the front surface, so none of the optical properties of the glass are used. Glass is chosen for its mechanical properties only; the 70 tonnes of glass is just a very elaborate support for 100 nm (about 30 g) of silver. Could one, by taking a radically new look at mirror design, suggest possible routes to the construction of larger mirrors which are much lighter (and therefore cheaper) than the present ones?

At the end, it is summarized in a material index, which is calculated for a few materials.

The following conclusions are taken:

The optimum material is CF’RP. The next best is polyurethane foam. Wood is obviously

impractical, but beryllium is good. Glass is better than steel, aluminium or concrete

(that is why most mirrors are made of glass), but a lot less good than beryllium, which

is used for mirrors when cost is not a concern.

But at the end, we find the inventive step:

The most obvious obstacle is the lack of stability of polymers – they change dimensions with age, humidity, temperature and so on. But glass itself can be foamed to give a material with a density not much larger than polyurethane foam, and the same stability as solid glass, so a study of this sort can suggest radically new solutions to design problems by showing how new classes of materials might be used.

Indeed, with low density cellular glass, we arrive at a material index = 0.1, which is the best value. However, with the usable dimensions of cellular glass (60 x 40 cm), the idea of building a large mirror cannot be realized with cellular glass. But the continous glass foaming technique as developed by GLAPOR allows dimensions up to 3.2 m. Even wider up to 6m (like for float glass) is possible in case there should a market for this large product. Indeed, light structures built from foamed recycled glass have a certain future.

Also Engineering Materials vol2 is available in pdf on nanotech. This book contains a nice chapter about glass and the production of glass articles. Also ceramics and more particular concrete are mentioned with a lot of data to be used for the calculation of an order of magnitude.

Also Engineering Materials vol2 is available in pdf on nanotech. This book contains a nice chapter about glass and the production of glass articles. Also ceramics and more particular concrete are mentioned with a lot of data to be used for the calculation of an order of magnitude.

This sounds like energy by cold fusion, but in this case it is real. Prof. Enrico Bernardo from the Engineering University of Padua invented a new process to foam glass below 80°C. The motivation for this invention is quite clear.

This sounds like energy by cold fusion, but in this case it is real. Prof. Enrico Bernardo from the Engineering University of Padua invented a new process to foam glass below 80°C. The motivation for this invention is quite clear. Enrico does not want to limit him self to the foaming of “easy” soda lime glass but he wants also foam glasses which are eager to crystallize. Such glasses are already crystallizing during sintering and does not foam due to the crystallization. Glasses obtained from waste incinerators (bottom ash, fly ash) are a typical example. In fact, all the efforts are based on the philosophy to recycle any waste.

Enrico does not want to limit him self to the foaming of “easy” soda lime glass but he wants also foam glasses which are eager to crystallize. Such glasses are already crystallizing during sintering and does not foam due to the crystallization. Glasses obtained from waste incinerators (bottom ash, fly ash) are a typical example. In fact, all the efforts are based on the philosophy to recycle any waste.

The book is of course illustrated with case studies. Hereunder we cite the case study about the support of a large telescope mirror.

The book is of course illustrated with case studies. Hereunder we cite the case study about the support of a large telescope mirror. The cost of a 5m telescope is, like the telescope itself, astronomical – about UKE120 m or US$180 m. This cost varies roughly with the square of the weight of the mirror so it rises very steeply as the diameter of the mirror increases. The mirror itself accounts for about 5% of the total cost of the telescope. The rest goes on the mechanism which holds, positions and moves the mirror as it tracks across the sky

The cost of a 5m telescope is, like the telescope itself, astronomical – about UKE120 m or US$180 m. This cost varies roughly with the square of the weight of the mirror so it rises very steeply as the diameter of the mirror increases. The mirror itself accounts for about 5% of the total cost of the telescope. The rest goes on the mechanism which holds, positions and moves the mirror as it tracks across the sky

Also Engineering Materials vol2 is available in pdf on

Also Engineering Materials vol2 is available in pdf on

The standard cellular glass like

The standard cellular glass like  and transport 200 kg, which is more than one typical pallet GLAPOR cellular glass. The drone can operate 30 minutes with one full battery. And now I dream about

and transport 200 kg, which is more than one typical pallet GLAPOR cellular glass. The drone can operate 30 minutes with one full battery. And now I dream about  A typical

A typical  Cellular concrete or AAC (

Cellular concrete or AAC ( The autoclaved aerated concrete products are made of

The autoclaved aerated concrete products are made of  For the low density, we observe:

For the low density, we observe:

In all cases, sand, lime (CaO) and gypsum (CaSO4) are bound with cement. The lime is produced by burning limestone at 800°C. Cement is produced from burning a mixture of limestone and clay at 1400°C and fine grinding the residue to a very fine powder. The foaming is done with Al powder and afterwards, autoclaving happens at 180°C and 12 bar to give the foam its strength. In both cases, a lot of water (more than 50%) is heated and evaporated. It is clear that the complete process, including the preparation of the “raw materials” is very energy intensive for the production of AAC.

In all cases, sand, lime (CaO) and gypsum (CaSO4) are bound with cement. The lime is produced by burning limestone at 800°C. Cement is produced from burning a mixture of limestone and clay at 1400°C and fine grinding the residue to a very fine powder. The foaming is done with Al powder and afterwards, autoclaving happens at 180°C and 12 bar to give the foam its strength. In both cases, a lot of water (more than 50%) is heated and evaporated. It is clear that the complete process, including the preparation of the “raw materials” is very energy intensive for the production of AAC. On the other hand, we could melt a soda lime glass at 1600°C with sand, sodaash, calcium sulphate and limestone. This glass can be ground to a fine powder and foamed above 800°C with carbon black or glycerin to a closed cell structure or with (fine) limestone to an open cell foam. However, the melting and foaming process is more energy intensive than the AAC process and also the investments are a lot larger due to the high temperatures used. At the end, cellular glass based on fresh raw materials is more expensive. It makes only sense to use this type of cellular glass instead of AAC in case closed cells are a must. This is typically the case in flat roofs and industrial insulation.

On the other hand, we could melt a soda lime glass at 1600°C with sand, sodaash, calcium sulphate and limestone. This glass can be ground to a fine powder and foamed above 800°C with carbon black or glycerin to a closed cell structure or with (fine) limestone to an open cell foam. However, the melting and foaming process is more energy intensive than the AAC process and also the investments are a lot larger due to the high temperatures used. At the end, cellular glass based on fresh raw materials is more expensive. It makes only sense to use this type of cellular glass instead of AAC in case closed cells are a must. This is typically the case in flat roofs and industrial insulation. But if a large pile of waste glass is ready to be recycled, it is clear that this glass has to be foamed to cellular glass with closed or open cells with only one temperature step at 800°C instead of producing cellular glass or cellular concrete with fresh raw materials like sand and limestone with multiple temperature steps. This third option is introduced by

But if a large pile of waste glass is ready to be recycled, it is clear that this glass has to be foamed to cellular glass with closed or open cells with only one temperature step at 800°C instead of producing cellular glass or cellular concrete with fresh raw materials like sand and limestone with multiple temperature steps. This third option is introduced by