2018 was indeed a fruitful year for the development of cellular glass. In a previous post, I already declared the Aalborg – Ljubljana team as the one who made the largest progress during the last year with consequences on the market the next years.

2018 was indeed a fruitful year for the development of cellular glass. In a previous post, I already declared the Aalborg – Ljubljana team as the one who made the largest progress during the last year with consequences on the market the next years.

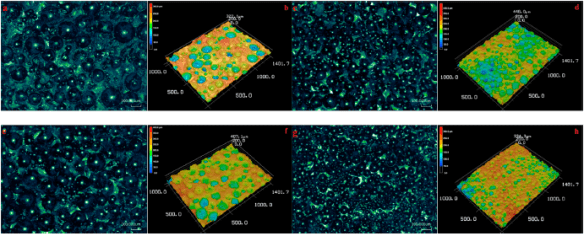

But yesterday, I found a new paper, published in 2018 with an extremely important experimental fact. This paper proves that it is possible to produce a glass foam with an homogeneous and CLOSED cell structure with only a melting step at 1100°C without grinding and sintering process. I give here under the abstract:

Glass foams are being widely used as constructional materials due to their unique properties in thermal insulation, fire retardation, and shockwave absorption. However, the cost of energy consumption and processes in a conventional glass foam production limited the use of glass foams as sustainable materials. In this study,

for the very first time, thermally tunable CaO−SnO2−P2O5−SiO2 glass foams with controllable pore size were presented as a novel category of melt-casting and float-manufacturable glasses. It was found that the pore size and thermal properties become tunable by manipulating the glass network, i.e., connecting linear chained Sn−P

network with [SiO4] units. In addition, the unique combination of thermal properties and porous structure of CaO−SnO2−P2O5−SiO2 glasses shows potential in float glass foam production, which can produce glass foams sheet-by-sheet with less complexity in

manufacturing processes.

This means that this glass foam can be formed with the floating method on a tin bath, generally know as the float glass process, invented by Sir Alistair Pilkington.

This means that this glass foam can be formed with the floating method on a tin bath, generally know as the float glass process, invented by Sir Alistair Pilkington.

This foam should have NOX gases in the cells but density, thermal conductivity and compressive strength are not given. The authors claims that this will be the route to low cost cellular glass. I see the following positive and negative points.

- By working with top rollers like for float glass, it could be possible to flatten the cells and to tune the couple thermal conductivity / compressive strength.

- There are no belts or molds which have to be replaced, molten tin is doing this.

- There is one heating step to 1100°C to be compared with a heating to 800°C after energy intensive grinding.

- The glass composition with phosphates and tin oxide is probably costly.

- It is not clear that replacing tin is less costly than replacing a steel belt or molds.

- A lot of (expensive) heat has to be extracted at the bottom of the tin bath to avoid that molten tin hits the steel casing.

- It is not clear how we keep the same temperature under and above the foam because heating the molten tin is not needed for float glass.

- A typical float glass line costs typically 130 000 000€ while a low cost cellular glass production line, based on direct foaming of waste glass costs less than 20 000 000€.

Nevertheless, this invention is of major importance especially when the waste glass becomes less available and in that way more expensive. In fact, we could speak about the continuous foaming second generation and it will be a major challenge to develop this new process. Alistair is dead, long live Alistair.

Nevertheless, this invention is of major importance especially when the waste glass becomes less available and in that way more expensive. In fact, we could speak about the continuous foaming second generation and it will be a major challenge to develop this new process. Alistair is dead, long live Alistair.

In a very short time, I see that phosphates are introduced in the cellular glass world. The first time as a crystallization inhibitor, the second time now for a “grinding-sintering free” cellular glass process.

It can be interesting to find out how people arrive at your blog. The blog “And the lightest beam is … cellular glass “, published in January 2018 is getting a lot of attention with an exponential growth.

It can be interesting to find out how people arrive at your blog. The blog “And the lightest beam is … cellular glass “, published in January 2018 is getting a lot of attention with an exponential growth.

Before the float glass process became developed, quality glass needed to be ground and polished to get a smooth surface. Like described

Before the float glass process became developed, quality glass needed to be ground and polished to get a smooth surface. Like described  Like shown in the previous blogs, the tin bath is suggested only to be used as transport carrier during the foaming of the glass. This is a much more expensive solution than the a belt which turns around within the furnace without leaving and so reheating. A glass fleece can be used to avoid sticking of the foam on the steel belt.

Like shown in the previous blogs, the tin bath is suggested only to be used as transport carrier during the foaming of the glass. This is a much more expensive solution than the a belt which turns around within the furnace without leaving and so reheating. A glass fleece can be used to avoid sticking of the foam on the steel belt. The more I think about using a tin bath, I see a lot of advantages evaporating if compared with a steel belt, turning around strictly inside the furnace. Especially the

The more I think about using a tin bath, I see a lot of advantages evaporating if compared with a steel belt, turning around strictly inside the furnace. Especially the

This means that this glass foam can be formed with the floating method on a tin bath, generally know as the

This means that this glass foam can be formed with the floating method on a tin bath, generally know as the  Nevertheless, this invention is of major importance especially when the waste glass becomes less available and in that way more expensive. In fact, we could speak about the continuous foaming second generation and it will be a major challenge to develop this new process. Alistair is dead, long live Alistair.

Nevertheless, this invention is of major importance especially when the waste glass becomes less available and in that way more expensive. In fact, we could speak about the continuous foaming second generation and it will be a major challenge to develop this new process. Alistair is dead, long live Alistair.

The

The  Cellular glasses are prime candidate materials for the structural substrate of mirrored glass for solar concentrator reflecting panels. These materials possess properties desirable for this application such as high stiffness to weight ratio, dimensional stability, projected low cost in mass production and, importantly, a close match in thermal expansion coefficient with that of the mirror glass. These materials are brittle, however, and susceptible to mechanical failure from slow crack growth caused by a stress corrosion mechanism.

Cellular glasses are prime candidate materials for the structural substrate of mirrored glass for solar concentrator reflecting panels. These materials possess properties desirable for this application such as high stiffness to weight ratio, dimensional stability, projected low cost in mass production and, importantly, a close match in thermal expansion coefficient with that of the mirror glass. These materials are brittle, however, and susceptible to mechanical failure from slow crack growth caused by a stress corrosion mechanism.

Foam glass gravel is a highly stable and versatile product that has been successfully used in building and infrastructure construction in Europe for over twenty-five years. Our mission is to bring this product to the construction industry in North America.

Foam glass gravel is a highly stable and versatile product that has been successfully used in building and infrastructure construction in Europe for over twenty-five years. Our mission is to bring this product to the construction industry in North America.

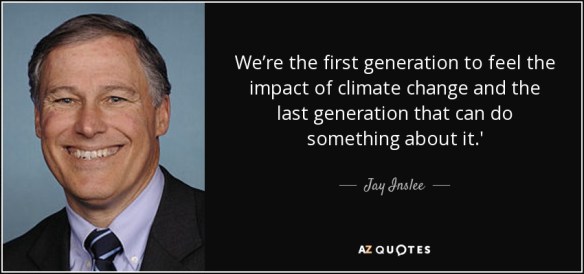

Foaming is commonly achieved by adding metal oxides or metal carbonates (foaming agents) to glass powder. At elevated temperature, the glass melt becomes viscous and the foaming agents decompose or react to form gas, resulting in foamy glass melt. Subsequent cooling to room temperature, lead to solid foam glass. Metal carbonates decompose due to surface reaction. Based on Na2CO3, we show the reaction is fast and the glass transition is changed considerably. We propose the reaction rate is dependent on contact area between glass melt and Na2CO3, melt viscosity and Na+ diffusion.

Foaming is commonly achieved by adding metal oxides or metal carbonates (foaming agents) to glass powder. At elevated temperature, the glass melt becomes viscous and the foaming agents decompose or react to form gas, resulting in foamy glass melt. Subsequent cooling to room temperature, lead to solid foam glass. Metal carbonates decompose due to surface reaction. Based on Na2CO3, we show the reaction is fast and the glass transition is changed considerably. We propose the reaction rate is dependent on contact area between glass melt and Na2CO3, melt viscosity and Na+ diffusion.  A method is developed for optimising process parameters. Characteristic temperatures are derived from a deformation curve and the deformation rate curve. Maximum expansion rate was linked to closed porosity. Using this knowledge the method is applied to literature data to analyse for optimal conditions. The resulting conditions were in agreement with industrial conditions. Since no foam glass properties are necessary to measure, the method allows fast investigation of process parameters.

A method is developed for optimising process parameters. Characteristic temperatures are derived from a deformation curve and the deformation rate curve. Maximum expansion rate was linked to closed porosity. Using this knowledge the method is applied to literature data to analyse for optimal conditions. The resulting conditions were in agreement with industrial conditions. Since no foam glass properties are necessary to measure, the method allows fast investigation of process parameters.  The melt viscosity is an important parameter for foam growth. We compared bubble- and crystal free melt viscosity with foam density and show in order to minimise the foam density, the heat-treatment should be performed in the viscosity regime of 103.7-106 Pa s.

The melt viscosity is an important parameter for foam growth. We compared bubble- and crystal free melt viscosity with foam density and show in order to minimise the foam density, the heat-treatment should be performed in the viscosity regime of 103.7-106 Pa s.  dependent on porosity or foam density. Foam glasses made from CRT panel glass and different foaming agents confirm this trend at high porosity level (85-97%). The experimental data suggests the solid conductivity is dependent on the foaming agent applied.

dependent on porosity or foam density. Foam glasses made from CRT panel glass and different foaming agents confirm this trend at high porosity level (85-97%). The experimental data suggests the solid conductivity is dependent on the foaming agent applied.

In 1991, he became a professor at the

In 1991, he became a professor at the  Since 1994, he has been a professor at the

Since 1994, he has been a professor at the  I got a

I got a