New Production Fills Critical Need for Foamed Glass Aggregates in Sustainable U.S. Building, Highway Construction and Landscape Architecture Applications

Eddystone, PA (January 15, 2019) – AeroAggregates, the first vertically-integrated manufacturer in North America to produce ultra-lightweight, closed cell foamed glass aggregates (FGA), has completed installation and is now operational on its second kiln, doubling production capacity to meet growing U.S. demand.

Eddystone, PA (January 15, 2019) – AeroAggregates, the first vertically-integrated manufacturer in North America to produce ultra-lightweight, closed cell foamed glass aggregates (FGA), has completed installation and is now operational on its second kiln, doubling production capacity to meet growing U.S. demand.

The kilns at AeroAggregates use 100 percent post-consumer recycled glass to produce a building aggregate that is lightweight, non-combustible, insulating, free-draining, non-absorbent, and resistant to chemicals, rot and acid. This makes FGA superior for construction, lightweight embankments, load distribution platforms and insulating subgrade, as well as lateral load reduction behind retaining walls and structures. Foamed glass aggregates also possess a highly frictional surface which makes it ideal as a lightweight backfill.

“Our ultra-lightweight FGA can solve the challenges of today’s infrastructure projects, especially for those that require fill to be placed over soft compressible materials, weight-bearing structures or over areas with sensitive underground infrastructure,” explained Archie Filshill, CEO and Co-Founder of AeroAggregates. “We’re excited to fire up our second kiln in order to meet increased demand from the civil engineering and construction markets that require sustainable, lightweight materials due to specialized design and constructability requirements.”

With the addition of the new AeroAggregates kiln, the equivalent of more than 140 million recycled curbside glass bottles (or 32,000 tons) will be diverted each year, bringing relief to municipal recycling operations. According to a recent study, municipal recycling programs spend approximately $150 million annually to dispose of unwanted glass. The FGA manufacturing process employed by AeroAggregates can utilize mixed color glass and due to its advanced cleaning system is unaffected by small amounts of residual paper and other contaminates.

The new 60-foot foamed glass kiln was imported from Europe where, for many years, FGA technology and manufacturing have been used heavily by the civil engineering market. A recent report by market research firm BauInfoConsult found that the European architects they surveyed intend to use more natural insulating materials (wood wool, hemp, cork and granules such as FGA) in upcoming residential and commercial construction projects reducing their use of polystyrene, polyurethane and polyisocyanurate. Unlike the non-combustible nature of FGA, materials like expanded and extruded polystyrene, commonly used when lightweight construction materials are specified, are falling out of favor in the industry due to their flammability.

The company’s unique FGA manufacturing process, obtained through an exclusive license from a Europe-based firm, starts with curbside recycled glass powder which is then mixed with a foaming agent. The mixed powder is sent through a kiln and softened by temperatures reaching 1,800 degrees Fahrenheit. During this process, the foaming agent creates bubbles within the softened glass, which ultimately creates foamed glass aggregates. The output produced is a remarkable material that creates a superior building product offering many sustainability benefits.

About AeroAggregates

AeroAggregates is the first vertically-integrated company in North America to produce ultra-lightweight closed cell FGA from 100 percent recycled glass. The company’s manufacturing capabilities include the ability to make several types of foamed glass including both open and closed cell aggregates. The founders of AeroAggregates realized the need for a sustainable solution for lightweight construction materials due to increased design or constructability requirements. Today’s civil engineering challenges include construction on soft soils, lateral load reduction behind retaining walls and structures, insulating subgrade and backfill, and the protection of underground utilities. AeroAggregates provides an answer to many of these challenges by supplying a lightweight material with a high friction angle that is also insulating, free-draining, non-absorbent, non-combustible, and resistant to chemicals, rot and acid. Its manufacturing plant is located in Eddystone, PA, a brownfield redevelopment site that was formerly the location of Baldwin Locomotive Works. Visit www.aeroaggregates.com for more information.

AeroAggregates is the first vertically-integrated company in North America to produce ultra-lightweight closed cell FGA from 100 percent recycled glass. The company’s manufacturing capabilities include the ability to make several types of foamed glass including both open and closed cell aggregates. The founders of AeroAggregates realized the need for a sustainable solution for lightweight construction materials due to increased design or constructability requirements. Today’s civil engineering challenges include construction on soft soils, lateral load reduction behind retaining walls and structures, insulating subgrade and backfill, and the protection of underground utilities. AeroAggregates provides an answer to many of these challenges by supplying a lightweight material with a high friction angle that is also insulating, free-draining, non-absorbent, non-combustible, and resistant to chemicals, rot and acid. Its manufacturing plant is located in Eddystone, PA, a brownfield redevelopment site that was formerly the location of Baldwin Locomotive Works. Visit www.aeroaggregates.com for more information.

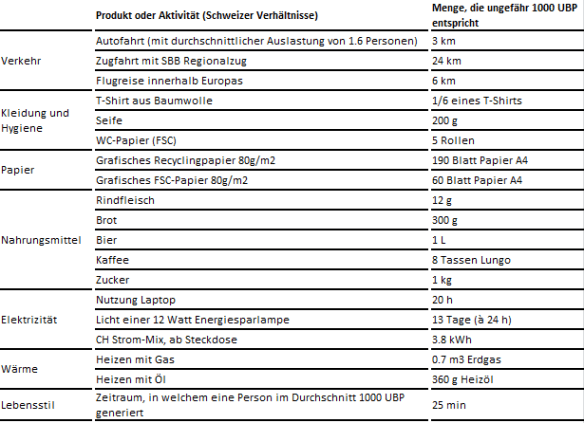

UBP is the German abbreviation of Umweltbelastungspunkte, which is a result of

UBP is the German abbreviation of Umweltbelastungspunkte, which is a result of  An

An

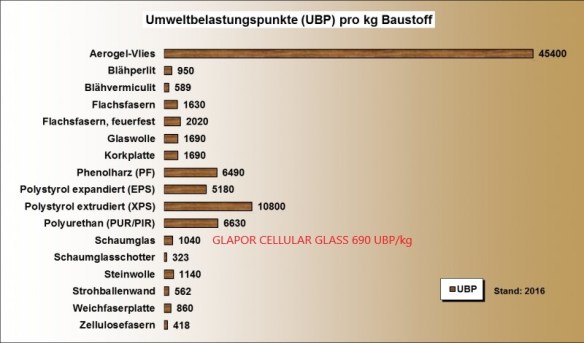

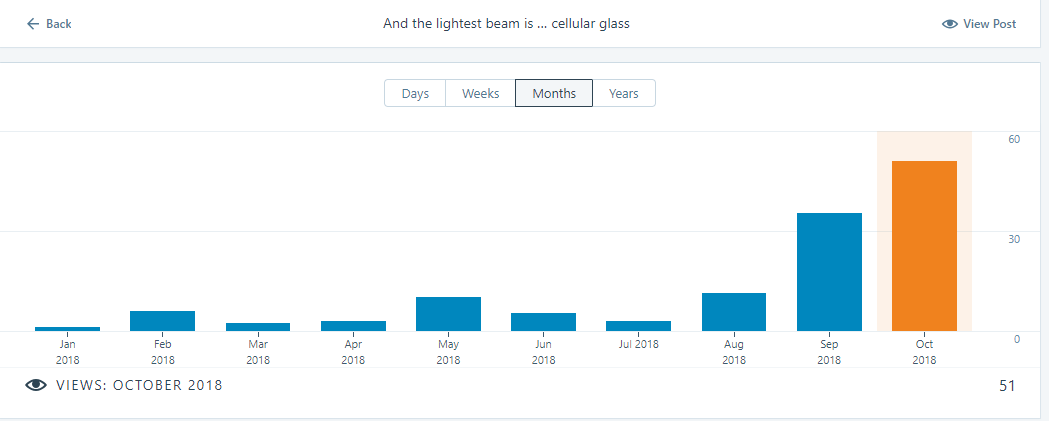

GLAPOR communicates 690 UBP per kg cellular glass board for production in Germany and delivery in Switzerland, which is lower than any thermal insulation except foamed glass gravel (also a GLAPOR product) like shown in the following figure. The improved value compared with “Schaumglas” is due to the fact that GLAPOR foams directly recycled glass without melting a special composition. In case production should be in Switzerland, the UBP lowers to 552 UBP/kg.

GLAPOR communicates 690 UBP per kg cellular glass board for production in Germany and delivery in Switzerland, which is lower than any thermal insulation except foamed glass gravel (also a GLAPOR product) like shown in the following figure. The improved value compared with “Schaumglas” is due to the fact that GLAPOR foams directly recycled glass without melting a special composition. In case production should be in Switzerland, the UBP lowers to 552 UBP/kg.

I remember that LATEX was really more difficult to use compared to Word Perfect but it was easy to include formula in your text. After the introduction of Word and Windows, I used Word or an open source version like

I remember that LATEX was really more difficult to use compared to Word Perfect but it was easy to include formula in your text. After the introduction of Word and Windows, I used Word or an open source version like  Today an excel-table is easily incorporated by using the (LATEX)

Today an excel-table is easily incorporated by using the (LATEX)  But in fact you don´t need to install software on your PC.

But in fact you don´t need to install software on your PC.

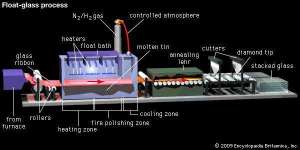

Before the float glass process became developed, quality glass needed to be ground and polished to get a smooth surface. Like described

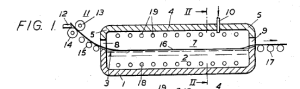

Before the float glass process became developed, quality glass needed to be ground and polished to get a smooth surface. Like described  Like shown in the previous blogs, the tin bath is suggested only to be used as transport carrier during the foaming of the glass. This is a much more expensive solution than the a belt which turns around within the furnace without leaving and so reheating. A glass fleece can be used to avoid sticking of the foam on the steel belt.

Like shown in the previous blogs, the tin bath is suggested only to be used as transport carrier during the foaming of the glass. This is a much more expensive solution than the a belt which turns around within the furnace without leaving and so reheating. A glass fleece can be used to avoid sticking of the foam on the steel belt. The more I think about using a tin bath, I see a lot of advantages evaporating if compared with a steel belt, turning around strictly inside the furnace. Especially the

The more I think about using a tin bath, I see a lot of advantages evaporating if compared with a steel belt, turning around strictly inside the furnace. Especially the

This means that this glass foam can be formed with the floating method on a tin bath, generally know as the

This means that this glass foam can be formed with the floating method on a tin bath, generally know as the  Nevertheless, this invention is of major importance especially when the waste glass becomes less available and in that way more expensive. In fact, we could speak about the continuous foaming second generation and it will be a major challenge to develop this new process. Alistair is dead, long live Alistair.

Nevertheless, this invention is of major importance especially when the waste glass becomes less available and in that way more expensive. In fact, we could speak about the continuous foaming second generation and it will be a major challenge to develop this new process. Alistair is dead, long live Alistair.

The

The