We already have written a post about Permafrost. Although this Permafrost is unknown in our regions, a lot of people have to make their lifes on such an underground. In the Northern Hemisphere, 24% of the ice-free land area, equivalent to 19 million square kilometers,[9]is more or less influenced by permafrost. Most of this area is found in Siberia, northern Canada, Alaska and Greenland.

We already have written a post about Permafrost. Although this Permafrost is unknown in our regions, a lot of people have to make their lifes on such an underground. In the Northern Hemisphere, 24% of the ice-free land area, equivalent to 19 million square kilometers,[9]is more or less influenced by permafrost. Most of this area is found in Siberia, northern Canada, Alaska and Greenland.

The basic problem to live on Permafrost is the stability because there is an active layer, which is melting every summer. Building on this layer makes that the building is continuous sinking into the underground.

The basic problem to live on Permafrost is the stability because there is an active layer, which is melting every summer. Building on this layer makes that the building is continuous sinking into the underground.

Above on the left, a standard building is “sinking” into the underground while at the right, the building is put on concrete pillars, deep into the permafrost with a concrete slab on top of this pillars to support all bending forces of the building. The havier the building (more concrete), the deeper the pillars are put into the permafrost (more concrete). Between the ground and the building, we have an airlayer, which avoids that building heat is penetrating into the permafrost, creating even more instability.

The new system replaces the active layer (about 1.5m) by cellular glass. Cellular glass is weight light, can support the building and 1.5m cellular glass avoids perfectly that building heat penetrates into the permafrost. Another advantage is that a climate change hardly influences the permafrost under the building. In that way a lot of concrete has been avoided.

The new system replaces the active layer (about 1.5m) by cellular glass. Cellular glass is weight light, can support the building and 1.5m cellular glass avoids perfectly that building heat penetrates into the permafrost. Another advantage is that a climate change hardly influences the permafrost under the building. In that way a lot of concrete has been avoided.

For this application, we don´t need cellular glass with the lowest thermal conductivity, which means that cellular glass, directly foamed from recycled glass will satisfy. This cellular glass can be prefabricated from large boards of 2.8 x 1.2m, today only produced by GLAPOR cellular glass. This can be done with the help of polyurea, like already done for flat roofs. Cellular glass gravel is less suited because it absorbs water, which freezes and increases the weight. I guess that the new construction is a better approach (more stable) and price competitive.

For this application, we don´t need cellular glass with the lowest thermal conductivity, which means that cellular glass, directly foamed from recycled glass will satisfy. This cellular glass can be prefabricated from large boards of 2.8 x 1.2m, today only produced by GLAPOR cellular glass. This can be done with the help of polyurea, like already done for flat roofs. Cellular glass gravel is less suited because it absorbs water, which freezes and increases the weight. I guess that the new construction is a better approach (more stable) and price competitive.

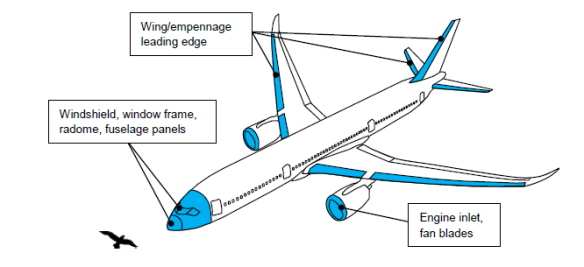

The article also shows the load deformation curve of the perfect kinetic energy absorber. This curve is typcial for foams and indeed also for cellular glass when the compressive strength measurement is done without capping. Indeed, the typical peak at the beginning of the flat part is absent for foams but not for honeycumbs.

The article also shows the load deformation curve of the perfect kinetic energy absorber. This curve is typcial for foams and indeed also for cellular glass when the compressive strength measurement is done without capping. Indeed, the typical peak at the beginning of the flat part is absent for foams but not for honeycumbs. The article shows also a graph with the specific kinetic absorption of foams, which do and do not comply with what is needed. The typical foams of polyurethane, polyisocianate and polyethylene do not comply, even at densities of 100 kg/m³. But on the other hand,

The article shows also a graph with the specific kinetic absorption of foams, which do and do not comply with what is needed. The typical foams of polyurethane, polyisocianate and polyethylene do not comply, even at densities of 100 kg/m³. But on the other hand,  The

The

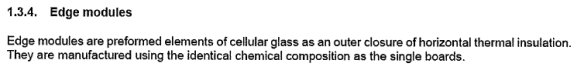

Sometimes, it is not clear why in some countries an application of cellular glass is allowed and in others not. In some cases, lobbying of competitive products could be the reason. In order to get a fairplay, Europe generates European Assessment Documents (

Sometimes, it is not clear why in some countries an application of cellular glass is allowed and in others not. In some cases, lobbying of competitive products could be the reason. In order to get a fairplay, Europe generates European Assessment Documents ( The European Assessment Document (EAD) is the documentation of the methods and criteria accepted in EOTA as being applicable for the assessment of the performance of a construction product in relation to its essential characteristics. The EAD is developed in all cases where the assessment of a construction product is not or not fully covered by a harmonised technical specification (Regulation (EU) No 305/2011).

The European Assessment Document (EAD) is the documentation of the methods and criteria accepted in EOTA as being applicable for the assessment of the performance of a construction product in relation to its essential characteristics. The EAD is developed in all cases where the assessment of a construction product is not or not fully covered by a harmonised technical specification (Regulation (EU) No 305/2011).

In this way, the GLAPOR RDS system cannot be blocked anymore by lobbying competition in a few countries. The RDS-blocks are typical edge modules with the same chemical composition as single boards and even the used cellular glass gravel.

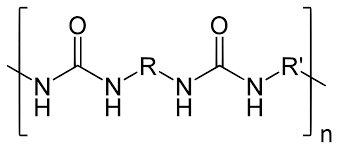

In this way, the GLAPOR RDS system cannot be blocked anymore by lobbying competition in a few countries. The RDS-blocks are typical edge modules with the same chemical composition as single boards and even the used cellular glass gravel. The weakness of cellular glass are its dusty surface, the lower tensile / bending strength and a rather weak surface. By applying polyurea, the dusty and weak surface are completely eliminated, while the large tensile strength / elongation eliminate the immidiate failure consequence of a crack in the cellular glass due to bending or tension. In fact, a board cellular glass, coated on all sides with polyurea behaves as an extremely robust light board. Standard polyurea is combustible with EUROCLASS F and removes an important strong point of cellular glass.

The weakness of cellular glass are its dusty surface, the lower tensile / bending strength and a rather weak surface. By applying polyurea, the dusty and weak surface are completely eliminated, while the large tensile strength / elongation eliminate the immidiate failure consequence of a crack in the cellular glass due to bending or tension. In fact, a board cellular glass, coated on all sides with polyurea behaves as an extremely robust light board. Standard polyurea is combustible with EUROCLASS F and removes an important strong point of cellular glass. But with the addition of some flame retarders,

But with the addition of some flame retarders,  Indeed, on the condition of a suitable Reaction to Fire classification, polyurea and cellular glass may be a good combination. A straightforward application could be a cellular glass flat roof, built with large cellular glass boards (less joints) where the water proofing membrane is replaced by polyurea.

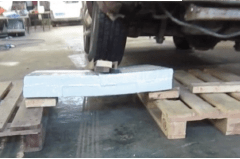

Indeed, on the condition of a suitable Reaction to Fire classification, polyurea and cellular glass may be a good combination. A straightforward application could be a cellular glass flat roof, built with large cellular glass boards (less joints) where the water proofing membrane is replaced by polyurea. Polyurea coated cellular glass has indeed a huge bending strength in relation to its weight like shown in this picture. Uncoated celllular glass never takes a weight of about 500 kg in these circumstances.

Polyurea coated cellular glass has indeed a huge bending strength in relation to its weight like shown in this picture. Uncoated celllular glass never takes a weight of about 500 kg in these circumstances. For a 2.8m long board, we have calculated that a minimum thickness of 10cm is needed to be on the very safe side. But great was our surprise that some cellular glass sales engineers claim that these boards cannot be produced although this was already shown in an

For a 2.8m long board, we have calculated that a minimum thickness of 10cm is needed to be on the very safe side. But great was our surprise that some cellular glass sales engineers claim that these boards cannot be produced although this was already shown in an

Such false stories, told to harm others are called a

Such false stories, told to harm others are called a