Walter Lovett was a professor of Civil Engineering at the University of Pittsburgh and made the following contribution on a conference about structural foams in 1960.

Walter Lovett was a professor of Civil Engineering at the University of Pittsburgh and made the following contribution on a conference about structural foams in 1960.

The first foamed glass was developed in this country in 1938 and was first placed on the market in 1942. Several factors contributed to the production of this material, but the most important were:

- An idea that there was a need for a waterproof, noncombustible, inorganic material of low density and low thermal conductivity to serve industry as an insulant.

- The Navy’s need for a material which would stand up well in salt water, be buoyant enough to float anti-submarine nets, and also withstand the action of enemy

Since the United States was at war during 1942, the larger part of the development of foamed glass was pointed toward the production of a buoyant item. From foamed glass, cubes were formed approximately 8′ on a side, protected on the outside by heavy planking. They were floated out into the mouths of harbors and rivers by the thousands, and there used to hold up steel anti-submarine nets. During the war years, the vast quantity of foamed glass produced was used for this purpose; however, some was also made available for use as an insulant for roofs, and as cold storage and wall insulation for humidity-controlled buildings such as exist in the textile industry.

Since the United States was at war during 1942, the larger part of the development of foamed glass was pointed toward the production of a buoyant item. From foamed glass, cubes were formed approximately 8′ on a side, protected on the outside by heavy planking. They were floated out into the mouths of harbors and rivers by the thousands, and there used to hold up steel anti-submarine nets. During the war years, the vast quantity of foamed glass produced was used for this purpose; however, some was also made available for use as an insulant for roofs, and as cold storage and wall insulation for humidity-controlled buildings such as exist in the textile industry.

The material is made by grinding a bora-silica type glass to about the consistency of portland cement. This fine glass powder, with a small addition of other ingredients, is placed in stainless steel pans and heated to about 17500F, which causes the material to foam. The material is then put through an annealing lehr (oven) to relieve any internal stresses, and then is cut into blocks of various thicknesses.

The primary use of foamed glass is for insulation, but it has been and is being used as a structural load-bearing material. For example, when the Central Mortgage and Housing Corporation of Canada was studying the need for low-cost housing, they first made a study of materials other than the conventional wood frame and the prefabricated wall system, which both involve numerous, time-consuming operations to fabricate and erect,

Central Mortgage and Housing’s requirements for an acceptable wall material were that the material must be strong, rigid and possess resistance to heat transfer, moisture transfer and fire, and preferably that it be homogeneous and easily mass-produced, After studying various materials, it was decided that foamed glass was the closest approach to the desired material. Having chosen the wall material, it was decided to build an experimental house in the industrial community of Ajax, Ontario. A basement-less house was chosen for this investigation consisting of two bedrooms, bathroom, combination dining and living room, kitchen and utility room.

The house was erected in the spring of 1949. The wall and interior partitions were prefabricated using 2″ x 12″ x 18″ thick foamed glass blocks bonded together with hot asphalt to form a 4″ thick panel. The joints between the blocks were staggered to assure an overlap. Window and door openings were made in the panels as they were fabricated. The edges of the panels were vertical construction joints to be made during erection and were coated with a thermoplastic adhesive which can be reactivated after it has hardened by applying heat.

Before erection, the surfaces of all partitions and exterior panels were covered with cloth set in ordinary oil base paint, over which one coat of paint was applied. Second coats of paint were added on the inside and outside walls for aesthetic reasons, and a decorative finish was applied to the interior walls.

The exposed edges of the panels were protected by wooden crating during transportation and stock piling.

The panels were erected by setting them on the concrete slab in a slow-setting adhesive compound. Aligning the vertical edges close together, a specially designed heater was inserted between the edges In order to reactivate the thermoplastic coating. To prevent heat from escaping, a vertical wood strip was placed over the joint. When the adhesive was reactivated, the heater and wood backing strip were removed, and the one panel was shoved manually against the other.

After all the wall panels were in place, the prefabricated plywood roof sections were hoisted into place and adhered to the top edges of the exterior and interior walls.

A look at the performance record of this foamed glass house reveals that it has been economical to heat since the 4″ wall has a 0.09 coefficient of thermal transmission. Also, the homogeneous foamed glass reduced the air infiltration to a minimum. In the coldest months, the tenant uses slightly over 80 gallons of oil. The greatest heat loss is at the perimeter of the concrete slab.

In addition to its resistance to heat transfer, this material has very good resistance to moisture penetration. Some small penetration occurred at the joints of panels. At these points, caulking compounds were applied which remedied the situation.

The house has weathered the elements for ten years and has proven structurally sound against high wind, including “Hurricane Hazel.” The cost of the experimental unit was $14, 117, This included all material, labor, trial installations and development work. It was estimated that the potential cost of the same unit produced on a mass-production basis and erected by an experienced crew would run about $7,600 using 1949 costs.

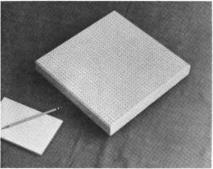

The newest use of foamed glass is in the acoustical absorption field. Foamed glass, as originally manufactured, is a completely closed-cell material. In order to give the material sound-absorbing properties, foamed glass with open cells has been developed. A unit is now being produced which measures 13-1/2″ x 13-1/2″ x 2-1/2″ having four 2.1/2″ square x 1/2″ thick pads on the back for mounting, to leave a 1/2″ air space behind each unit. This unit is designed to be used as a “patch absorber,”

The newest use of foamed glass is in the acoustical absorption field. Foamed glass, as originally manufactured, is a completely closed-cell material. In order to give the material sound-absorbing properties, foamed glass with open cells has been developed. A unit is now being produced which measures 13-1/2″ x 13-1/2″ x 2-1/2″ having four 2.1/2″ square x 1/2″ thick pads on the back for mounting, to leave a 1/2″ air space behind each unit. This unit is designed to be used as a “patch absorber,”

These foamed glass units (Fig. 1) are incombustible, rigid, and dimensionally stable. They will not shrink, warp or change dimension with changes of temperature or humidity. The units are especially designed as a sound-conditioning material to provide the architect or designer with a product whose prime function is sound absorption, diffusion and control. By the proper placement and spacing of these units in a room, the reverberation time and diffusion of the sound waves may be closely controlled.

These foamed glass units (Fig. 1) are incombustible, rigid, and dimensionally stable. They will not shrink, warp or change dimension with changes of temperature or humidity. The units are especially designed as a sound-conditioning material to provide the architect or designer with a product whose prime function is sound absorption, diffusion and control. By the proper placement and spacing of these units in a room, the reverberation time and diffusion of the sound waves may be closely controlled.

Let us look at how the foamed glass sound absorbers are adapted in a room to provide good listening conditions. For example, if we decided that a particular room is to have a certain desired reverberation time, and calculated that “x” amount of Sabina of absorption is required, knowing the number of Sabina required, we divide this figure by two which gives the number of absorbers required, since each foamed glass unit absorbs an average of 2.0 Sabina over the speech frequency range.

Let us look at how the foamed glass sound absorbers are adapted in a room to provide good listening conditions. For example, if we decided that a particular room is to have a certain desired reverberation time, and calculated that “x” amount of Sabina of absorption is required, knowing the number of Sabina required, we divide this figure by two which gives the number of absorbers required, since each foamed glass unit absorbs an average of 2.0 Sabina over the speech frequency range.

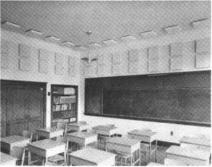

For good acoustics, the sound reflection must be diffused and must not give a directional impression. To accomplish this, the absorbing units should be distributed on the surfaces of a room and not concentrated on one surface or in large areas. This can be done by the “spot-and-patch” technique. This consists of spacing absorbers to provide contrasting reflection and absorption surfaces. With foamed glass unit absorbers, this is easily done because of the independent unit design that allows spaced or cluster mounting on wall and ceiling areas.

For good acoustics, the sound reflection must be diffused and must not give a directional impression. To accomplish this, the absorbing units should be distributed on the surfaces of a room and not concentrated on one surface or in large areas. This can be done by the “spot-and-patch” technique. This consists of spacing absorbers to provide contrasting reflection and absorption surfaces. With foamed glass unit absorbers, this is easily done because of the independent unit design that allows spaced or cluster mounting on wall and ceiling areas.

In general, the upper areas of the wall and perimeter areas of ceilings in from the wall are used for mounting the units. In classrooms or auditoriums, the units are placed in larger numbers around and toward the listening (audience) end. At the speaking end, the units are few or nonexistent, for reflective reinforcement. In areas of general noise (cafeterias, swimming pools, etc.) the units are placed uniformly around wall and ceiling areas. Figure 2 shows foamed glass absorbers being placed on the wall. Figure 3 shows a classroom treatment, and Figure 4 shows the units on the walls and ceiling of a swimming pool.

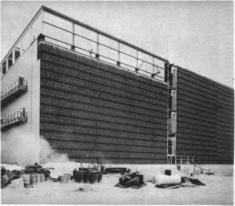

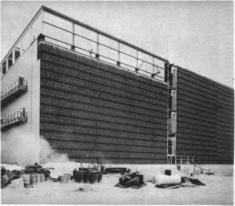

Another use of foamed glass has been in the construction of cold storage warehouses. Blocks of foamed glass have been erected and fastened to the steel framework forming the outside wall where they also serve as insulation. Foamed glass blocks have also been placed between or over bulb purling to form the structural roof deck. Figure 5 shows foamed glass being erected against the outside framework of a large freezer.

Another use of foamed glass has been in the construction of cold storage warehouses. Blocks of foamed glass have been erected and fastened to the steel framework forming the outside wall where they also serve as insulation. Foamed glass blocks have also been placed between or over bulb purling to form the structural roof deck. Figure 5 shows foamed glass being erected against the outside framework of a large freezer.

Figure 6 shows foamed glass being used on a large brewery. Foamed glass walls built in this manner are usually 7″ to 8″ thick and are erected in two layers, with horizontal and vertical joints staggered to prevent any thermal short circuit. The outside of the wall Is usually finished with stucco or metal siding. If metal siding is used, horizontal wood sleepers are imbedded in the outer layer of foamed glass to facilitate fastening of the metal.

Figure 6 shows foamed glass being used on a large brewery. Foamed glass walls built in this manner are usually 7″ to 8″ thick and are erected in two layers, with horizontal and vertical joints staggered to prevent any thermal short circuit. The outside of the wall Is usually finished with stucco or metal siding. If metal siding is used, horizontal wood sleepers are imbedded in the outer layer of foamed glass to facilitate fastening of the metal.

One might question how this construction stands up structurally. Wind load tests have been run on a ICV -0″ x Z01-0″ x 8″ thick foamed glass wall panel. Before excessive deflection took place, the wind velocity exceeded 78 mph. The panel tested did not have an outside finish, which would add to the structural strength. Also, the foamed glass is rigid, having an ultimate compressive strength of 100 lbs. per sq. in., and the material is not affected by moisture or changes of humidity, which insures against sagging or buckling of the wall.

One might question how this construction stands up structurally. Wind load tests have been run on a ICV -0″ x Z01-0″ x 8″ thick foamed glass wall panel. Before excessive deflection took place, the wind velocity exceeded 78 mph. The panel tested did not have an outside finish, which would add to the structural strength. Also, the foamed glass is rigid, having an ultimate compressive strength of 100 lbs. per sq. in., and the material is not affected by moisture or changes of humidity, which insures against sagging or buckling of the wall.

Walter Lovett was a visionary in 1960. We discussed the above in a few blogs about 55 years later: floating , Acoustic absorption with cellular glass and Houses with cellular glass walls.

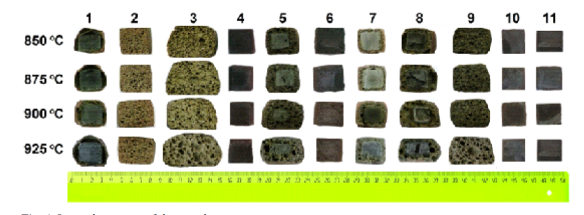

Everywhere in the world, small cellular glass companies are popping up. Most of them are based on direct foaming of recycled glass. Taiwan is another example with Taiwan Material Development Co., Ltd.

Everywhere in the world, small cellular glass companies are popping up. Most of them are based on direct foaming of recycled glass. Taiwan is another example with Taiwan Material Development Co., Ltd. Innovation, Green energy, Quality, and Service are the purpose of Taiwan Material Development Co., LTD, and become the greatest sustainable operation green material industry is our goal. We provide high quality construction and guarantee in building material, construction, techniques, and after-sales service, and also reduce the waste of energy resources. We provide a healthy, environment friendly, convenience and high quality functional material. TWMD introduce AH lightweight solid wall to market, and provide users the internal wall partition with all function. On the other hand, we keep developing related green building materials. Look forward to developing a complete production system. To build a green building material brand. Hope to satisfied architects, interior designers, businesses of related industries and ordinary people by doing one-stop shopping.

Innovation, Green energy, Quality, and Service are the purpose of Taiwan Material Development Co., LTD, and become the greatest sustainable operation green material industry is our goal. We provide high quality construction and guarantee in building material, construction, techniques, and after-sales service, and also reduce the waste of energy resources. We provide a healthy, environment friendly, convenience and high quality functional material. TWMD introduce AH lightweight solid wall to market, and provide users the internal wall partition with all function. On the other hand, we keep developing related green building materials. Look forward to developing a complete production system. To build a green building material brand. Hope to satisfied architects, interior designers, businesses of related industries and ordinary people by doing one-stop shopping.![]() They describe their product as a Lightweight Insulation block, foamed from LCD glass, obtained from Spring Pool Glass. This means that they are foaming a borosilicate glass. This kind of glass has a lower thermal expansion coefficient and higher chemical resistance, which means that this product can withstand more than standard cellular glass. It is not clear how this glass is foamed because LCD glass does not contain sulphate because it is sodium free. I guess it will be carbon black and Antimonytrioxide.

They describe their product as a Lightweight Insulation block, foamed from LCD glass, obtained from Spring Pool Glass. This means that they are foaming a borosilicate glass. This kind of glass has a lower thermal expansion coefficient and higher chemical resistance, which means that this product can withstand more than standard cellular glass. It is not clear how this glass is foamed because LCD glass does not contain sulphate because it is sodium free. I guess it will be carbon black and Antimonytrioxide.

Since the United States was at war during 1942, the larger part of the development of foamed glass was pointed toward the production of a buoyant item. From foamed glass, cubes were formed approximately 8′ on a side, protected on the outside by heavy planking. They were floated out into the mouths of harbors and rivers by the thousands, and there used to hold up steel anti-submarine nets. During the war years, the vast quantity of foamed glass produced was used for this purpose; however, some was also made available for use as an insulant for roofs, and as cold storage and wall insulation for humidity-controlled buildings such as exist in the textile industry.

Since the United States was at war during 1942, the larger part of the development of foamed glass was pointed toward the production of a buoyant item. From foamed glass, cubes were formed approximately 8′ on a side, protected on the outside by heavy planking. They were floated out into the mouths of harbors and rivers by the thousands, and there used to hold up steel anti-submarine nets. During the war years, the vast quantity of foamed glass produced was used for this purpose; however, some was also made available for use as an insulant for roofs, and as cold storage and wall insulation for humidity-controlled buildings such as exist in the textile industry. The newest use of foamed glass is in the acoustical absorption field. Foamed glass, as originally manufactured, is a completely closed-cell material. In order to give the material sound-absorbing properties, foamed glass with open cells has been developed. A unit is now being produced which measures 13-1/2″ x 13-1/2″ x 2-1/2″ having four 2.1/2″ square x 1/2″ thick pads on the back for mounting, to leave a 1/2″ air space behind each unit. This unit is designed to be used as a “patch absorber,”

The newest use of foamed glass is in the acoustical absorption field. Foamed glass, as originally manufactured, is a completely closed-cell material. In order to give the material sound-absorbing properties, foamed glass with open cells has been developed. A unit is now being produced which measures 13-1/2″ x 13-1/2″ x 2-1/2″ having four 2.1/2″ square x 1/2″ thick pads on the back for mounting, to leave a 1/2″ air space behind each unit. This unit is designed to be used as a “patch absorber,” These foamed glass units (Fig. 1) are incombustible, rigid, and dimensionally stable. They will not shrink, warp or change dimension with changes of temperature or humidity. The units are especially designed as a sound-conditioning material to provide the architect or designer with a product whose prime function is sound absorption, diffusion and control. By the proper placement and spacing of these units in a room, the reverberation time and diffusion of the sound waves may be closely controlled.

These foamed glass units (Fig. 1) are incombustible, rigid, and dimensionally stable. They will not shrink, warp or change dimension with changes of temperature or humidity. The units are especially designed as a sound-conditioning material to provide the architect or designer with a product whose prime function is sound absorption, diffusion and control. By the proper placement and spacing of these units in a room, the reverberation time and diffusion of the sound waves may be closely controlled. Let us look at how the foamed glass sound absorbers are adapted in a room to provide good listening conditions. For example, if we decided that a particular room is to have a certain desired reverberation time, and calculated that “x” amount of Sabina of absorption is required, knowing the number of Sabina required, we divide this figure by two which gives the number of absorbers required, since each foamed glass unit absorbs an average of 2.0 Sabina over the speech frequency range.

Let us look at how the foamed glass sound absorbers are adapted in a room to provide good listening conditions. For example, if we decided that a particular room is to have a certain desired reverberation time, and calculated that “x” amount of Sabina of absorption is required, knowing the number of Sabina required, we divide this figure by two which gives the number of absorbers required, since each foamed glass unit absorbs an average of 2.0 Sabina over the speech frequency range. For good acoustics, the sound reflection must be diffused and must not give a directional impression. To accomplish this, the absorbing units should be distributed on the surfaces of a room and not concentrated on one surface or in large areas. This can be done by the “spot-and-patch” technique. This consists of spacing absorbers to provide contrasting reflection and absorption surfaces. With foamed glass unit absorbers, this is easily done because of the independent unit design that allows spaced or cluster mounting on wall and ceiling areas.

For good acoustics, the sound reflection must be diffused and must not give a directional impression. To accomplish this, the absorbing units should be distributed on the surfaces of a room and not concentrated on one surface or in large areas. This can be done by the “spot-and-patch” technique. This consists of spacing absorbers to provide contrasting reflection and absorption surfaces. With foamed glass unit absorbers, this is easily done because of the independent unit design that allows spaced or cluster mounting on wall and ceiling areas. Another use of foamed glass has been in the construction of cold storage warehouses. Blocks of foamed glass have been erected and fastened to the steel framework forming the outside wall where they also serve as insulation. Foamed glass blocks have also been placed between or over bulb purling to form the structural roof deck. Figure 5 shows foamed glass being erected against the outside framework of a large freezer.

Another use of foamed glass has been in the construction of cold storage warehouses. Blocks of foamed glass have been erected and fastened to the steel framework forming the outside wall where they also serve as insulation. Foamed glass blocks have also been placed between or over bulb purling to form the structural roof deck. Figure 5 shows foamed glass being erected against the outside framework of a large freezer. Figure 6 shows foamed glass being used on a large brewery. Foamed glass walls built in this manner are usually 7″ to 8″ thick and are erected in two layers, with horizontal and vertical joints staggered to prevent any thermal short circuit. The outside of the wall Is usually finished with stucco or metal siding. If metal siding is used, horizontal wood sleepers are imbedded in the outer layer of foamed glass to facilitate fastening of the metal.

Figure 6 shows foamed glass being used on a large brewery. Foamed glass walls built in this manner are usually 7″ to 8″ thick and are erected in two layers, with horizontal and vertical joints staggered to prevent any thermal short circuit. The outside of the wall Is usually finished with stucco or metal siding. If metal siding is used, horizontal wood sleepers are imbedded in the outer layer of foamed glass to facilitate fastening of the metal. One might question how this construction stands up structurally. Wind load tests have been run on a ICV -0″ x Z01-0″ x 8″ thick foamed glass wall panel. Before excessive deflection took place, the wind velocity exceeded 78 mph. The panel tested did not have an outside finish, which would add to the structural strength. Also, the foamed glass is rigid, having an ultimate compressive strength of 100 lbs. per sq. in., and the material is not affected by moisture or changes of humidity, which insures against sagging or buckling of the wall.

One might question how this construction stands up structurally. Wind load tests have been run on a ICV -0″ x Z01-0″ x 8″ thick foamed glass wall panel. Before excessive deflection took place, the wind velocity exceeded 78 mph. The panel tested did not have an outside finish, which would add to the structural strength. Also, the foamed glass is rigid, having an ultimate compressive strength of 100 lbs. per sq. in., and the material is not affected by moisture or changes of humidity, which insures against sagging or buckling of the wall.

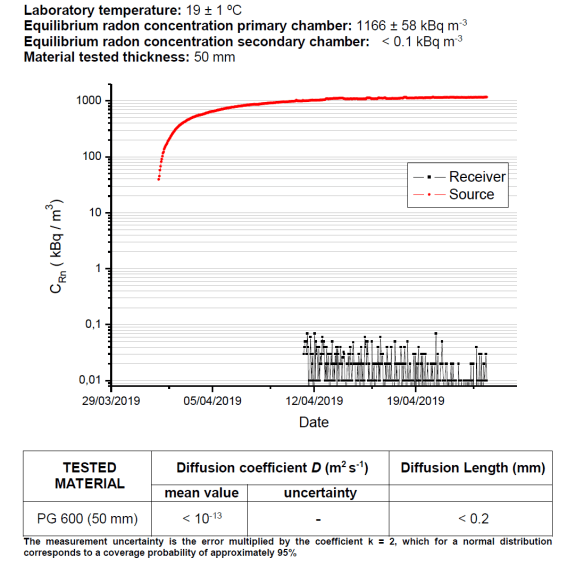

If cellular glass is vapour tight, we can expect that it is also Radon tight. But this logic is not accepted by our lawyer world. For that reason,

If cellular glass is vapour tight, we can expect that it is also Radon tight. But this logic is not accepted by our lawyer world. For that reason,

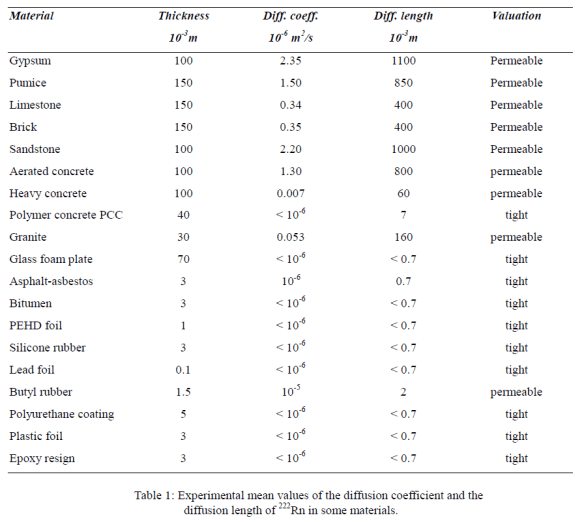

Indeed, a layer of 50 mm cellular glass is 250 times the diffusion length, which means that Radon cannot diffuse through the cellular glass without decaying in the cellular glass. In that way, it is impossible that Radon decays in the lungs of humans and animals behind the cellular glass.

Indeed, a layer of 50 mm cellular glass is 250 times the diffusion length, which means that Radon cannot diffuse through the cellular glass without decaying in the cellular glass. In that way, it is impossible that Radon decays in the lungs of humans and animals behind the cellular glass. It is needed to install the boards with hot bitumen (

It is needed to install the boards with hot bitumen ( Like described in this

Like described in this

The American government educates its citizen how to build houses to avoid Radon accumulation like shown in this

The American government educates its citizen how to build houses to avoid Radon accumulation like shown in this

But like already mentionned in a previous

But like already mentionned in a previous