We are currently studying the technology to produce float glass. In a lot of cases, float glass is used as base material to foam directly or to remelt with addition of other raw materials and to be foamed later on.

We are currently studying the technology to produce float glass. In a lot of cases, float glass is used as base material to foam directly or to remelt with addition of other raw materials and to be foamed later on.

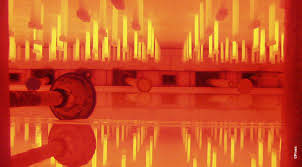

But since GFT joined CNUD EFCO, we are also interested about the tin bath. Molten tin and hot glass cannot be mixed and for that reason, we can produce window glass direcly on the molten tin. But could we do this also with cellular glass?

But since GFT joined CNUD EFCO, we are also interested about the tin bath. Molten tin and hot glass cannot be mixed and for that reason, we can produce window glass direcly on the molten tin. But could we do this also with cellular glass?

Could we put a glass powder with foaming agent on the molten tin and let it foam? In that case, we don´t need a belt or a mold, which are expensive parts in the production process. They have to be replaced regularly and are also heated to 850°C in the foaming process, consuming a lot of primary energy. Also the complete investment of rollers and drive systems can be skipped. On top of that, the typical belt coating with kaoline is not needed anymore, the glass foam does not stick on the molten tin.

Could we put a glass powder with foaming agent on the molten tin and let it foam? In that case, we don´t need a belt or a mold, which are expensive parts in the production process. They have to be replaced regularly and are also heated to 850°C in the foaming process, consuming a lot of primary energy. Also the complete investment of rollers and drive systems can be skipped. On top of that, the typical belt coating with kaoline is not needed anymore, the glass foam does not stick on the molten tin.

The technology to protect the molten tin for oxidation can be used for the foaming with carbon black, where a reducing atmosphere is always needed. The foaming processes with glycerin can probaly skip or reduce the use of water glass while the SiC process can remain unchanged.

The use of (graphite) fenders for thicker glass is now available to make a perfect rectangular foam (low waste) while top rollers can be used to stretch the cellular glass for an improved thermal conductivity or even to compress the cellular glass for an improved compressive strength without changing density. The bottom of the foam does probably not need any facing improving the efficiency of the process even more. I guess a foaming efficiency close to 90% becomes possible (90 % of the glass is sold as foam).

The use of (graphite) fenders for thicker glass is now available to make a perfect rectangular foam (low waste) while top rollers can be used to stretch the cellular glass for an improved thermal conductivity or even to compress the cellular glass for an improved compressive strength without changing density. The bottom of the foam does probably not need any facing improving the efficiency of the process even more. I guess a foaming efficiency close to 90% becomes possible (90 % of the glass is sold as foam).

Heating above the glass can be done with gas burners, which are also generating the reducing atmosphere. Heating under the foam has to be done in another way, keeping the temperature of the bottom of the foam equal to the top.

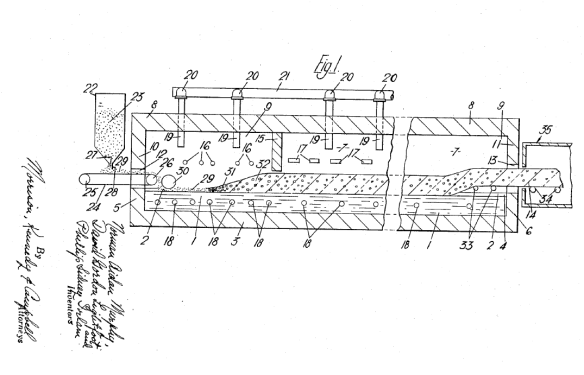

The largest part of the above is already published in an old US3361550 patent from 1964, when commercial float glass was born. The general remark on this idea is that a tin bath is too expensive compared with a normal foaming furnace. It is my conviction that a much simpler tin bath can be constructed for this purpose because we don´t have to produce perfect transparant glass without any distortion. The payback is made with less primary energy and refractory steel use and a larger flexibility. The answer on the above question is YES, this is the second generation continuous foaming.

And if we combine this with a small glass melting furnace, we could foam on a molten glass plate. This cellular glass should have one absolutely hard surface, which is frost resistant, could have any color wanted and is absolutely flat. If a less smooth surface is allowed, we could work with two layers of powder: one non-foaming and one foaming. The idea for a new generation cellular glass is born.

The same university also did some foaming of Cathode Ray Tube glass from old televisons. This is given in the following

The same university also did some foaming of Cathode Ray Tube glass from old televisons. This is given in the following  Another

Another

GLAPOR is based in

GLAPOR is based in  To match constantly rising demand, a second facility (‘Werk B’) was in 1925 constructed on Hüblteichstrasse and the total number of workers increased to just over 300 in the same year. The second facility was in 1937 followed by a third, ‘Werk C’, located on Schulgartenstrasse. The whole factory used standard coal-fired kilns before completely switching to gas-fired tunnel kilns early in the 1950’s.

To match constantly rising demand, a second facility (‘Werk B’) was in 1925 constructed on Hüblteichstrasse and the total number of workers increased to just over 300 in the same year. The second facility was in 1937 followed by a third, ‘Werk C’, located on Schulgartenstrasse. The whole factory used standard coal-fired kilns before completely switching to gas-fired tunnel kilns early in the 1950’s. A huge fire completely destroyed the ‘Werk C’ part of the facility in 1988 and the required reconstruction took until 1989. With all three locations fully operational again, the factory had a production area of 20,000 square meters and a workforce of around 800 people. The Mitterteich A.G. seemed to cope quite well with the overall situation on the German market. But in August 2005 the small city was rocked by the news that the company, represented by the board of directors, had to file for bankruptcy. For the 360 workers (70 percent of these female), it came as a shock. The small hope of an investor being able to save the company was destroyed by the local banks, who did not want to support the Mitterteich facility any longer. On March 1st 2006 the doors leading to the factory closed for the last time.

A huge fire completely destroyed the ‘Werk C’ part of the facility in 1988 and the required reconstruction took until 1989. With all three locations fully operational again, the factory had a production area of 20,000 square meters and a workforce of around 800 people. The Mitterteich A.G. seemed to cope quite well with the overall situation on the German market. But in August 2005 the small city was rocked by the news that the company, represented by the board of directors, had to file for bankruptcy. For the 360 workers (70 percent of these female), it came as a shock. The small hope of an investor being able to save the company was destroyed by the local banks, who did not want to support the Mitterteich facility any longer. On March 1st 2006 the doors leading to the factory closed for the last time.

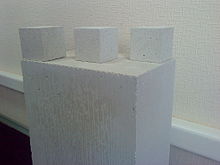

While the lowest density for AAC is about 350 kg/m³ , cellular glass can be foamed to 100 kg/m³. As a consequence, the thermal conductivity of AAC is much larger (0.11 W/mK) in comparison with GLAPOR cellular glass (0.050 W/mK) even in case of an equivalent compressive strength (0.06 W/mK). It means that we need the double thickness with AAC to obtain the same thermal resistance.

While the lowest density for AAC is about 350 kg/m³ , cellular glass can be foamed to 100 kg/m³. As a consequence, the thermal conductivity of AAC is much larger (0.11 W/mK) in comparison with GLAPOR cellular glass (0.050 W/mK) even in case of an equivalent compressive strength (0.06 W/mK). It means that we need the double thickness with AAC to obtain the same thermal resistance. AAC needs about 200 kWh/m³ primary energy for the production while

AAC needs about 200 kWh/m³ primary energy for the production while  In that case, it is not clear whether it will be boards or gravel. Like shown in this

In that case, it is not clear whether it will be boards or gravel. Like shown in this  Nevertheless, Australia is familar with reycling of glass like shown in this

Nevertheless, Australia is familar with reycling of glass like shown in this  It is clear that a cellular glass plant, converting recycled glass into cellular glass boards and gravel would be the ideal solution to value the recycling efforts of the Australian citizens. Indeed, cellular glass resists the harsh climate of Australia by its high softening point (above 700°C) and all kind of animals, which are

It is clear that a cellular glass plant, converting recycled glass into cellular glass boards and gravel would be the ideal solution to value the recycling efforts of the Australian citizens. Indeed, cellular glass resists the harsh climate of Australia by its high softening point (above 700°C) and all kind of animals, which are