We know that natural gas and crude oil will be gone within maximum 100 years. I am sure that I will not “enjoy” this situation but I guess everybody wants to be the Elon Musk in its own field. And yes, the world should be happy with this kind of guys, because the others (we) were able to consume in 150 years what earth could save in about 4000 million years.

We know that natural gas and crude oil will be gone within maximum 100 years. I am sure that I will not “enjoy” this situation but I guess everybody wants to be the Elon Musk in its own field. And yes, the world should be happy with this kind of guys, because the others (we) were able to consume in 150 years what earth could save in about 4000 million years.

The energy, radiated by the sun can be converted in electricity by absorbing wind energy, due to temperature gradients on earth and by solar – electricity converters using photovoltaïc or ORC on a liquid, heated with sunshine and parabolic mirrors.

For the production of glass, the technique of electric melting with electrodes, injecting energy in the liquid glass is well known. For the glass foaming, electric heating seems logic but some recipes need a reducing atmosphere, generated with gas burners, feeded with an excess of natural gas. That will be a problem which can be solved by the techniques, used in the tin bath of a float glass plant. Other recipes, like the GLAPOR – method, are foaming in a neutral atmophere and electric heaters can simply replace the burners.

But the energy density of gas burners is a lot larger than the one of electrical heaters. Working with a longer furnace (and longer foaming time at lower temperature) is of course possible but we can also consider the old fashion wood gas (syngas).Wood gas was used during World War II, where natural gas and crude oil were not available and is proven technology. The gas can be liquified to have a certain buffer. Today, technology with more performance is available, even as a hobby.

This mixture (syngas) of H2 and CO is obtained by gasifying wood. A rather limited wood (700 ha for 100 000m³ / year cellular glass ) is able to produce enough energy to drive a cellular glass plant in a constant way. If cellular glass plant and wood production are combined, losses due to energy transport are eliminated while the foaming of the glass is in that case CO2 neutral. On top of that, foaming recipes with a reducing atmosphere can also be foamed.

However, converting wood in wood gas to foam the glass is in fact an avoidable step. I am dreaming now about a layer of fine ground wood (pellets), a layer glass powder / foaming agent and a top layer of fine ground wood. This sandwich is transported on a belt, turning around in a furnace, electrical or wood gas heated, just to compensate the heat loss through the furnace walls. The burning of the wood induces the foaming of the glass in the most efficient way possible. This last idea can easily be tested in a small furnace.

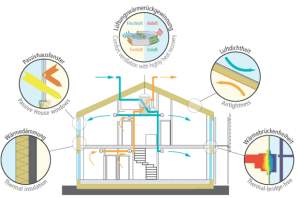

The durable thermal insulation cellular glass, saving tons of CO2 during use can be produced in a CO2 neutral way from just sunshine and waste glass. This cellular glass can be used to build the shell and floor insulation of durable passive houses with a wooden & plaster board inside structure, eliminating the use of cement. Solar cells (photo-voltaic and water boiler) on the cellular glass shell and Elon Musk’s Power Wall batteries inside the house are generating the energy needed for a comfortable living in a CO2 free way. The whole climate catastrophe is in fact pure bad will of human kind because the above is certainly not rocket science. Nevertheless, the bunch of climate negationists, supported today by a certain Donald Trump, have also the legal right to have their opinion. Elon Musk for president, I call him tomorrow.

I am well aware that professional sculptors will not be interested. They use hard and noble materials like stone, hard wood, bronze, … . But I think now on sculptors, who lost part of their craft by a handicap. I can imagine that they still “see” what they want to sculpture but have not the force anymore.

I am well aware that professional sculptors will not be interested. They use hard and noble materials like stone, hard wood, bronze, … . But I think now on sculptors, who lost part of their craft by a handicap. I can imagine that they still “see” what they want to sculpture but have not the force anymore.

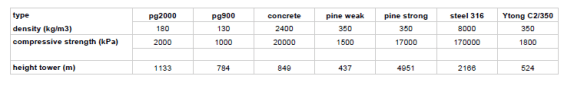

The PG900 is commercial available material from

The PG900 is commercial available material from