Greta Thunberg is the young Swedish girl, who kicked the ass of most adults towards a more ecologic world to avoid a climate catastrophe. The fossil addicted adults react quite aggressively like most addicted people, not becoming their drug anymore. Nevertheless, Sweden wants to

Greta Thunberg is the young Swedish girl, who kicked the ass of most adults towards a more ecologic world to avoid a climate catastrophe. The fossil addicted adults react quite aggressively like most addicted people, not becoming their drug anymore. Nevertheless, Sweden wants to  become the first fossil free country, the latest in 2045. This move is already extended to Europe by Ursula von der Leyen for a CO2-neutral Europe in 2050.

become the first fossil free country, the latest in 2045. This move is already extended to Europe by Ursula von der Leyen for a CO2-neutral Europe in 2050.

This decision has large consequences for the production of cellular glass. Indeed, today about 95% of the foaming of glass is done with fossil energy, primarily natural gas. For the foaming, glass powder, mixed with a foaming agent, has to be heated to above 800°C.

This decision has large consequences for the production of cellular glass. Indeed, today about 95% of the foaming of glass is done with fossil energy, primarily natural gas. For the foaming, glass powder, mixed with a foaming agent, has to be heated to above 800°C.

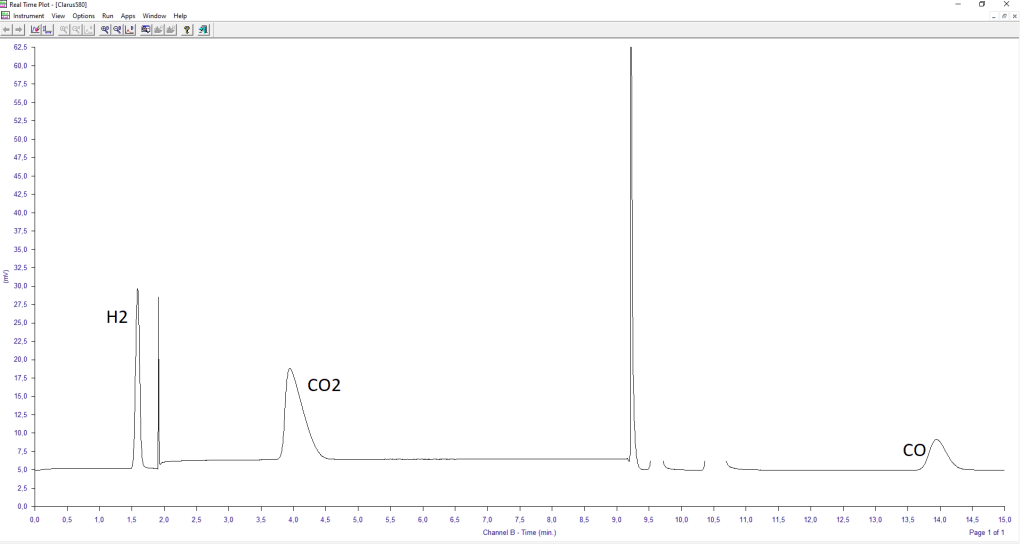

For the foaming of gravel, SiC (dry process) or glycerin / water glass (wet process) are used and both foaming recipes can be done in air without protective air. For that reason, GLASOPOR in Norway changed from fossil to electric heating. As a consequence, their CO2-emission per m³ decreased from 35 kg to 7 kg, like shown in the old and new EPD. I guess they use renewable electricity produced by water or wind.

The company STESS, producing Neoporm and already mentioned in a previous blog was also using a recipe, which was able to foam nicely in an electric furnace, like I have observed with my own eyes once in Wuppertal. It seems to be based on an organic foaming agent and water glass.

On the other hand, it is well known that foaming with carbon (black) (valid for 95% of the cellular glass boards) needs a protective atmosphere to avoid burning of the foaming agent before sintering of the glass. In case this process has to be done with electric heating, it will be necessary to generate a protective atmosphere with separate means. One way is the solution of float glass, where Nitrogen, mixed with 5% Hydrogen is injected into the furnace above the tin bath through the roof to avoid oxidation of the tin. This solution is quite expensive while a tin bath can be much better closed against air than a foaming furnace.

It is clear that before 2050 the cellular glass world has to be converted to electric heating with alternative recipes or expensive equipment to avoid early oxidation of the foaming agent. Greta has really impact, I am proud on that girl and I will do my part of it.

Recently, a nice YouTube-movie appeared about full printing a 3D-house. The house was put on GLAPOR cellular glass gravel, while the flat roof was insulalted with GLAPOR-boards.

Recently, a nice YouTube-movie appeared about full printing a 3D-house. The house was put on GLAPOR cellular glass gravel, while the flat roof was insulalted with GLAPOR-boards.

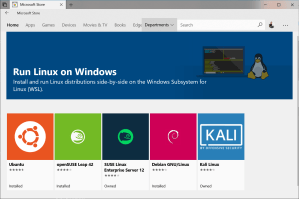

WSL-Ubuntu can be run as in a terminal of (as an example) MobaXterm. The X-server of MobaXterm (free for home-use) makes the GUI possible. We have succesfully installed and used

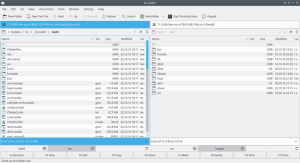

WSL-Ubuntu can be run as in a terminal of (as an example) MobaXterm. The X-server of MobaXterm (free for home-use) makes the GUI possible. We have succesfully installed and used It is possble to enter the Windows filesystem, which is mounted under /mnt and in this way, Linux and Windows-applications can be run on the same files. A C-complier and Python2 and python3 interpreters are already standard availbale with WSL-Ubuntu. The ordinary scientist has everything for his standard scientific work with this WSL-Ubuntu.

It is possble to enter the Windows filesystem, which is mounted under /mnt and in this way, Linux and Windows-applications can be run on the same files. A C-complier and Python2 and python3 interpreters are already standard availbale with WSL-Ubuntu. The ordinary scientist has everything for his standard scientific work with this WSL-Ubuntu. We may speculate about Windows 11. Will it be totally based on LINUX and in that way make all other LINUX-distros unnecessary? I would not be surprised. In the mean time, I enjoy the feeling that a community of free of charge working programmers clearly influence the decision of a large multinational.

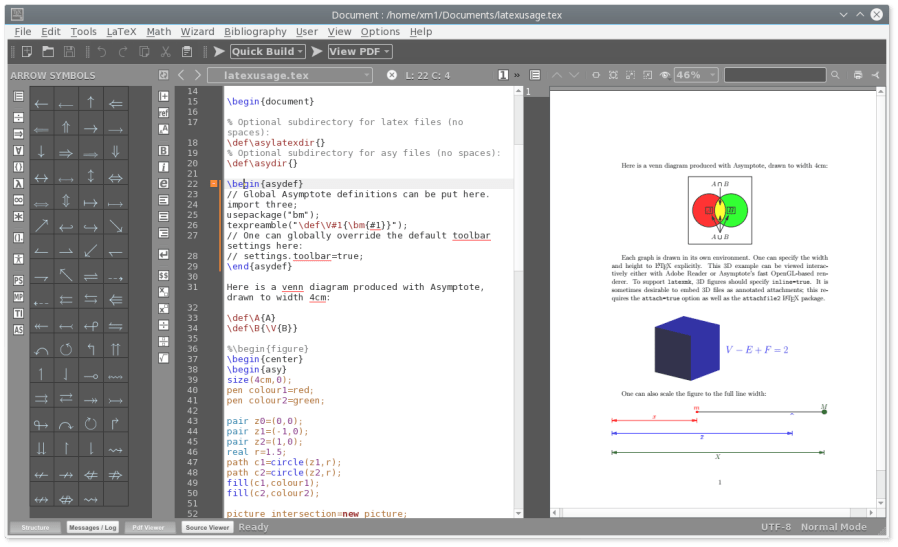

We may speculate about Windows 11. Will it be totally based on LINUX and in that way make all other LINUX-distros unnecessary? I would not be surprised. In the mean time, I enjoy the feeling that a community of free of charge working programmers clearly influence the decision of a large multinational. I made some new programs myselves and I found out that structured programming without GOTO, COMMON, … statements is very wel possible with FORTRAN90 for all our typical numerical programs. Structures of different types of variables can be described while subroutines can be collected in modules. C-functions can be merged in a FORTRAN program. Moreover, object oriented programming and parallel programming is also possible in FORTRAN 2003 and 2008, but I do not use that for the moment. Recently, also a GUI is available in order to make the program userfriendly with buttons and graphs. In case only a graph is needed, including

I made some new programs myselves and I found out that structured programming without GOTO, COMMON, … statements is very wel possible with FORTRAN90 for all our typical numerical programs. Structures of different types of variables can be described while subroutines can be collected in modules. C-functions can be merged in a FORTRAN program. Moreover, object oriented programming and parallel programming is also possible in FORTRAN 2003 and 2008, but I do not use that for the moment. Recently, also a GUI is available in order to make the program userfriendly with buttons and graphs. In case only a graph is needed, including  Some time ago, I was

Some time ago, I was  A lot of free FORTRAN source is available with the

A lot of free FORTRAN source is available with the  The Raspberry Pi on the other hand is a cheap computer, developed to run with LINUX, in this case the Debian based

The Raspberry Pi on the other hand is a cheap computer, developed to run with LINUX, in this case the Debian based  become the first

become the first  This decision has large consequences for the production of cellular glass. Indeed, today about 95% of the foaming of glass is done with fossil energy, primarily natural gas. For the foaming, glass powder, mixed with a foaming agent, has to be heated to above 800°C.

This decision has large consequences for the production of cellular glass. Indeed, today about 95% of the foaming of glass is done with fossil energy, primarily natural gas. For the foaming, glass powder, mixed with a foaming agent, has to be heated to above 800°C.

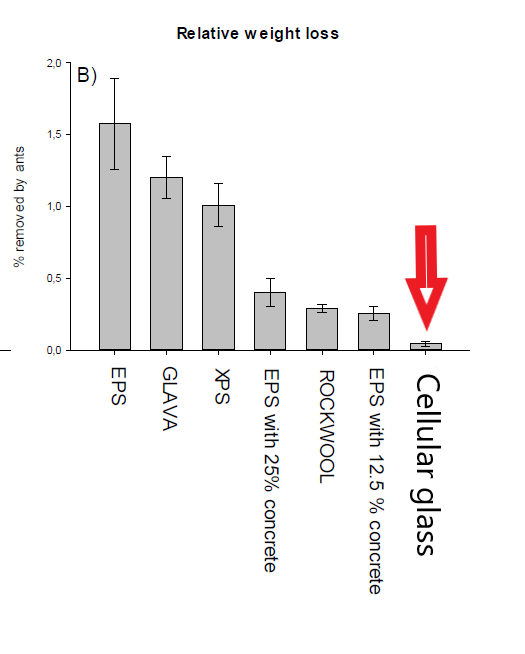

Ants

Ants