Flat solar collectors to heat water have still a large future with an efficiency up to 85% compared with photovoltaic, which is still only 15%. A typical solar collector consists of a glass pane, which allows transmission with minimum refelection of sun radiation on fluid cooled heat exchanger, which is thermally insulated at the backside. This insulation will be mineral because temperatures above the glass temperature of polystyrene (90°C) or another polymer can be expected.

Flat solar collectors to heat water have still a large future with an efficiency up to 85% compared with photovoltaic, which is still only 15%. A typical solar collector consists of a glass pane, which allows transmission with minimum refelection of sun radiation on fluid cooled heat exchanger, which is thermally insulated at the backside. This insulation will be mineral because temperatures above the glass temperature of polystyrene (90°C) or another polymer can be expected.

Cellular glass as thermal insulation was out of the question due to price and dimensions. Indeed, 0.60 x 0.45m boards for solar collectors of 2m x 1m are difficult to use. In the picture, the heat exchanger tube is put on mineral wool in an Al casing for only 245€ VAT included. The efficiency of this cheap solar collector is 75% (cold fluid at entrance) and without fluid flow, the temperature may become up to 208°C. With water, we could attain a pressure of 20 bar in that case, which means we need for example ethyleen glycol (EG) or propyleen glycol (PG) as safe liquid. They have a high boiling point (EG=197°C; PG=188°C) and low freezing point (EG=-12.9°C; PG=-59°C). With a fluid flow rate of 100l/hour, we have a pressure drop of 50 mbar.

Cellular glass as thermal insulation was out of the question due to price and dimensions. Indeed, 0.60 x 0.45m boards for solar collectors of 2m x 1m are difficult to use. In the picture, the heat exchanger tube is put on mineral wool in an Al casing for only 245€ VAT included. The efficiency of this cheap solar collector is 75% (cold fluid at entrance) and without fluid flow, the temperature may become up to 208°C. With water, we could attain a pressure of 20 bar in that case, which means we need for example ethyleen glycol (EG) or propyleen glycol (PG) as safe liquid. They have a high boiling point (EG=197°C; PG=188°C) and low freezing point (EG=-12.9°C; PG=-59°C). With a fluid flow rate of 100l/hour, we have a pressure drop of 50 mbar.

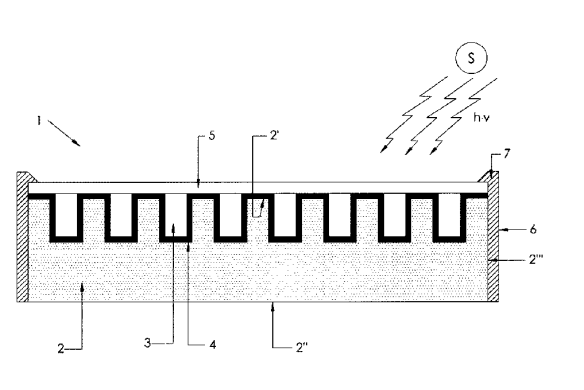

For that reason, we could consider to replace the mineral wool with meander tube by a large GLAPOR cellular glass board with the meander channel, milled directly into the cellular glass. The glass cover (eventual a double pane) closes the channel at the top. In this case, the radiation is absorbed directly into the water reducing the temperature gradient between solar radiation aborber and water. This means that the water will be warmer in winter reducing the need for extra heating.

However, this idea is not new. Patent DE102014007805A1 from end 2015 describes exactly the above.

However, an earlier PatentanmeldungWO2012093062A2 (2011) describes also such a system based on foamed glass from recycling glass.

This patent was based on research, sponsord by the German government and performed at the Univerity of Freiberg. This is the second time we met this university in the cellular glass world. It was first with vacuum cellular glass and now with a solar collector.

This patent was based on research, sponsord by the German government and performed at the Univerity of Freiberg. This is the second time we met this university in the cellular glass world. It was first with vacuum cellular glass and now with a solar collector.

A solar collector based on large cellular glass boards with the above structure should be much cheaper than the standard equipment, which is today used with a higher efficiency. Cellular glass is heat absorber, thermal insulation and casing at the same time. The difficult problem will be the connection of these cellular glass channels to metal tubes to be able to connect the solar collector on the system. But this problem can be solved with one of the many adhesives on the market. The major problem, the avialability of large cellular glass boards 2.8 x 1.2m is already solved by GLAPOR cellular glass.