Glass is used to produce wool (glass wool) and foam (cellular glass). Mineral wool can also be produced from basalt. The following picture shows both with a large magnification.

Glass is used to produce wool (glass wool) and foam (cellular glass). Mineral wool can also be produced from basalt. The following picture shows both with a large magnification.

wool foam

The principle of both thermal insulations is to hold a (still) gas and to block radiation. In the left one, the solid fibers have only point contact and are contributing only slightly to the thermal conductivity. The thermal gas conduction is the main contributor in the heat transport. In the right one, the foam holds the gas and in case of closed cells, we can choose a low conductivity gas like CO2. But the solid structure contributes much more to the thermal conductivity. It is clear that the thermal conductivity may be slightly lower for the wool structure, even under vacuum (VIP). But we all know that a higher thermal conductivity can be compensated by a larger thickness.

The fibers are kept together with a binder but nevertheless, both mineral thermal insulations can be considered as non-combustible.

The fiber structure allows the transport of gas, liquid and vapours and even the heat pipe effect is possible. The closed cellular structure does not allow transport of liquids, gas or vapour. That is clearly a bonus for the cellular structure. Secondary heat transport effects are excluded for the closed cellular structure.

But it must be clear without any calculation that the cellular structure should have a much better mechanical stability for the same density. Point contacts are highly mechanically unstable, even with a binder. For example, Rockwool CRS has a density of 150 kg/m³ and a compressive stress of 50 kPa at 10% creep. A cellular structure like GLAPOR PG900.2 can sustain 300 kPa ( 6 times !!!!) forever with a negligible creep at the same density. Nevertheless, fiber structures are much more sold for flat roofs than cellular structures, although the roof is loaded in tension by wind and in compression by walking maintenance people.

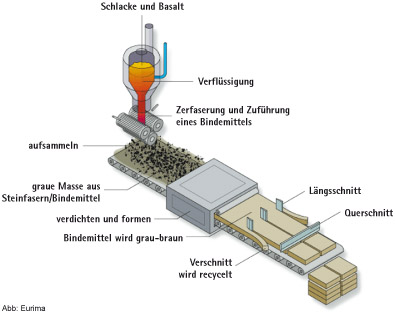

The logic explanation should be the old story that cellular glass is much more expensive but that is even hard to understand. Mineral fibers are formed after heating raw materials (basalt, waste) at 1600°C and another 200°C step for the binder. The above GLAPOR PG900.2 is manufactured by foaming ground waste glass with glycerin at 800°C. After correction for the thermal conductivity (thicker layer), both should have a comparable price.

GLAPOR cellular glass has indeed today a comparable price thanks to the introduction of new technologies in the old world of cellular glass. And indeed, the thermal insulation market becomes aware of the new opportunities resulting in a booming market.

Pingback: Popular post: Mineral wool versus foam | BELGLAS BVBA