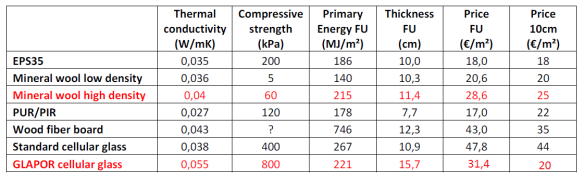

GLAPOR cellular glass is foamed from recycled glass without any remelting. As a consequence, the production equipment does not need a glass melter. In this way, the OPEX and CAPEX are seriously reduced, which allows to bring this material on the market at an interesting price. The use of a melting furnace should allow to improve the thermal conductivity of GLAPOR cellular glass with 20% for the same compressive strength but almost doubles the primary energy consumption. In case the thickness is not limited, GLAPOR cellular glass is an interesting economic and ecologic option, as shown in the following table.

GLAPOR cellular glass is foamed from recycled glass without any remelting. As a consequence, the production equipment does not need a glass melter. In this way, the OPEX and CAPEX are seriously reduced, which allows to bring this material on the market at an interesting price. The use of a melting furnace should allow to improve the thermal conductivity of GLAPOR cellular glass with 20% for the same compressive strength but almost doubles the primary energy consumption. In case the thickness is not limited, GLAPOR cellular glass is an interesting economic and ecologic option, as shown in the following table.

The table is based on two public reports already mentioned in previous posts about mineral wool and an ecology study. FU is a functional unit, which is equivalent with 10cm EPS35 or a thermal resistance of 2.857 m².K/W. The data for GLAPOR cellular glass were communicated by GLAPOR, while the high density mineral wool data for the primary energy are extrapolated from 105 to 145 kg/m³ density.

In case non-combustibility, a higher compressive strength, water and vapor tightness are important (for example flat roof), GLAPOR cellular glass is very a good ecologic and economic option if a larger thickness can be installed.